In the realm of fluid management systems, the Y type strainer stands out as an essential component for ensuring operational efficiency and equipment longevity. According to a recent market analysis by the International Fluid Dynamics Association, the demand for filtration systems, including Y type strainers, is projected to grow at a compound annual growth rate (CAGR) of 5.2% over the next five years. This surge in usage emphasizes the critical role these strainers play in preventing particulate contamination, thus safeguarding machinery and reducing maintenance costs.

Industry expert Dr. John Reynolds, a leading authority in industrial filtration systems, asserts, "Utilizing a Y type strainer can effectively minimize wear and tear on pumps and valves by trapping debris before it enters the system." With the implementation of proper installation techniques and a thorough understanding of their benefits, users can optimize their systems for both performance and reliability. This guide aims to provide comprehensive insights into the advantages of Y type strainers and practical tips for their installation, ensuring that users can harness the full potential of these vital components in their operations.

Y type strainers are essential components used in various piping systems to filter out debris and contaminants from fluids. They are designed in a 'Y' shape, which allows for effective filtering while minimizing pressure loss. The primary function of a Y type strainer is to protect downstream equipment such as pumps, valves, and heat exchangers from damage caused by particles. Their design facilitates easy maintenance, as the strainer element can be readily accessed for cleaning or replacement without needing to remove the entire strainer from the pipeline.

Understanding how Y type strainers work involves recognizing the two main flow paths. The fluid enters through the inlet side, moves through the strainer element, and exits via the outlet. As the fluid passes through, solid particles are captured by the straining mechanism, typically a mesh or perforated screen, allowing for a clean flow downstream. The angled design not only aids in filtering but also helps sediment settle at the bottom, ensuring efficient operation. This type of strainer is widely used in various applications, including water supply systems, HVAC, and industrial processes, emphasizing the importance of maintaining a clean fluid environment for optimal performance.

This chart illustrates the benefits of using Y Type Strainers, highlighting the percentage of users that identified specific advantages in a recent survey.

Y type strainers are essential components in various industrial applications, serving as a reliable means to protect piping systems from debris and contaminants. One of the key benefits of using a Y type strainer is its efficiency in maintaining the flow of fluids while preventing potential damage to downstream equipment. By installing a Y type strainer, operators can ensure that the system continues to function smoothly, minimizing downtime and costly repairs due to particle accumulation.

In addition to protecting equipment, Y type strainers offer versatility across multiple applications, including water treatment, chemical processing, and HVAC systems. Their design allows for easy maintenance; the screen can be cleaned without removing the strainer from the pipeline, which is particularly advantageous in environments where continuous operation is critical. With their compact design, Y type strainers can be easily integrated into existing systems, providing a straightforward solution for filtration needs while optimizing overall performance.

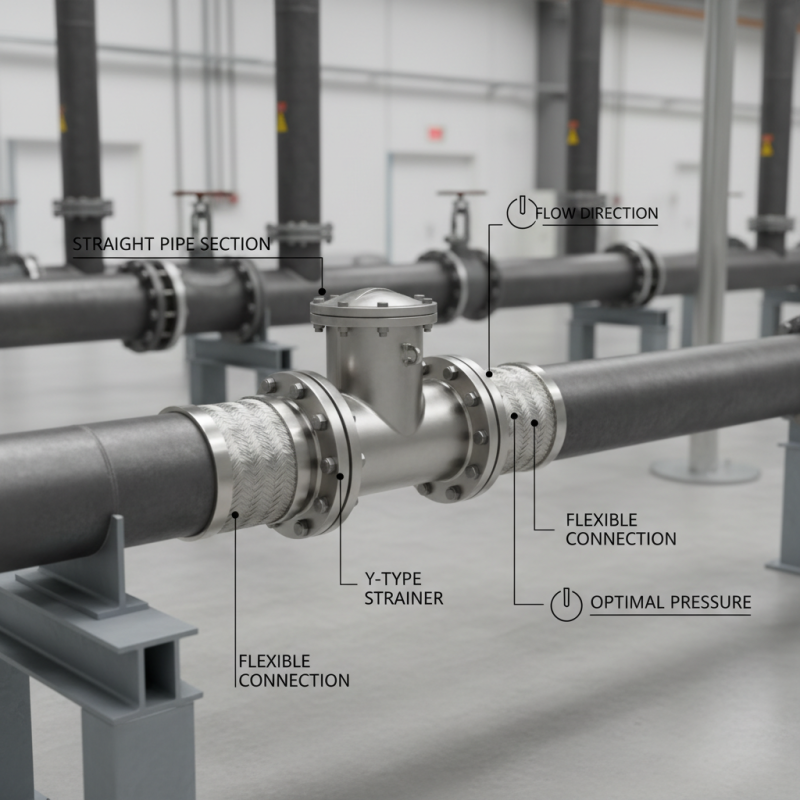

When installing a Y Type strainer, one of the first essential tips is to ensure proper orientation. The strainer should be installed in a horizontal position for optimal flow and sediment collection. This orientation allows debris to settle effectively in the strainer body, preventing clogs and maintaining system efficiency. Additionally, it is crucial to leave enough space around the strainer for future maintenance, such as cleaning or replacing the strainer elements.

Another important consideration is the selection of the right size strainer for your specific application. An incorrectly sized strainer can lead to inadequate filtration and increased pressure drops, potentially causing system inefficiencies. Always consult the system specifications and flow rates to choose a strainer that meets the demands of your pipeline. Lastly, ensure that the connections to the strainer are secure and leak-free. Utilizing proper gaskets and following torque specifications during installation will help prevent leakage and ensure long-lasting performance.

| Feature | Description | Benefits | Installation Tips |

|---|---|---|---|

| Material | Commonly made from stainless steel, bronze, or plastic. | Corrosion resistance, longevity, and suitability for various fluids. | Choose material based on fluid characteristics and environmental conditions. |

| Filtering Efficiency | Filters out particles and debris from fluids. | Prevents damage to downstream equipment and improves performance. | Ensure proper mesh size is selected for the application. |

| Maintenance | Requires regular cleaning and inspection. | Extends the life of the strainer and maintains system performance. | Develop a maintenance schedule based on operational conditions. |

| Flow Direction | Designed for a specific flow direction. | Ensures optimal filtering performance and reduces back pressure. | Confirm flow direction during installation to avoid reverse flow issues. |

| Size Options | Available in various sizes to fit different pipe diameters. | Facilitates compatibility with existing piping systems. | Select size based on pipe specifications and flow requirements. |

When installing Y type strainers, a common challenge faced by technicians is ensuring proper alignment within the pipeline. Misalignment can lead to excessive pressure drops and inadequate filtration performance. According to a study by the American Society of Mechanical Engineers (ASME), improper installations account for up to 25% of strainer-related issues in industrial applications. To mitigate this risk, it's essential to use accurate measurement tools and install the strainer in a straight section of the pipeline, where possible. Additionally, employing flexible connections can help accommodate minor misalignments.

Another frequent challenge during installation is the selection of the appropriate mesh size for the strainer. The National Fluid Power Association (NFPA) suggests that the chosen mesh should correspond to the specific application needs, typically based on the type of debris expected in the fluid. For instance, using a finer mesh in a system with larger particulate matter can lead to premature clogging, which results in operational inefficiencies. It is advisable to conduct a thorough analysis of the fluid characteristics and potential contaminants to ensure optimal strainer performance. Regular maintenance checks and monitoring the system's pressure drop can further aid in preventing issues related to strainer selection and installation.

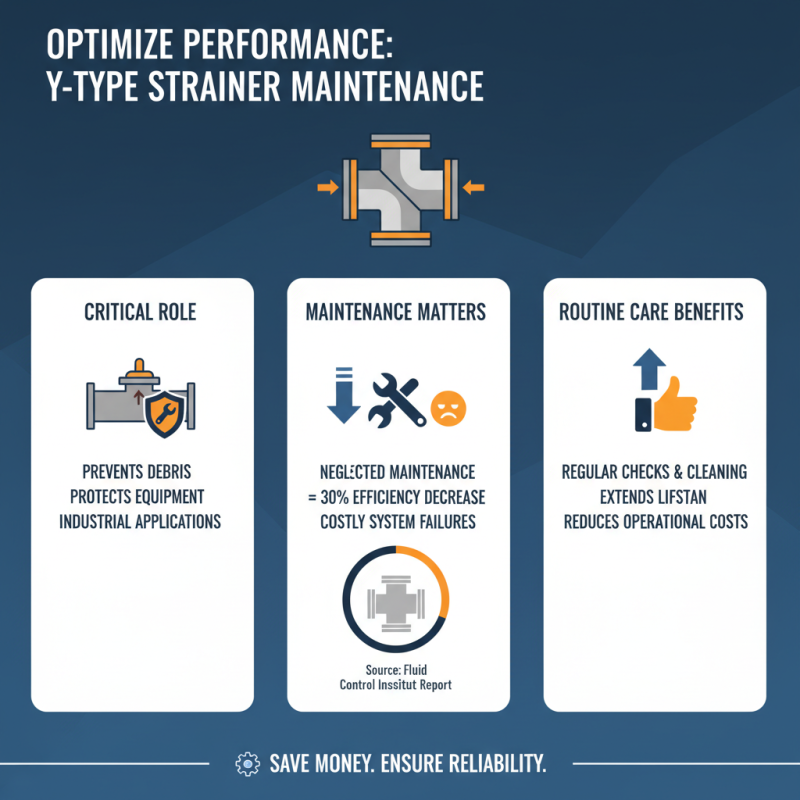

Y Type strainers play a critical role in various industrial applications by preventing debris from entering pipelines and damaging equipment. To ensure their optimal performance, regular maintenance is essential. According to a report by the Fluid Control Institute, neglecting maintenance can lead to a 30% decrease in efficiency and potentially costly system failures. Routine checks and cleaning can extend the lifespan of Y Type strainers, ultimately saving on operational costs.

One effective maintenance practice includes inspecting the strainer mesh for clogs or damage. A clogged strainer can cause increased pressure drop, which may affect the overall system performance. It is recommended to clean the strainer at least once every six months or more frequently if the strainers are exposed to high levels of particulates. Additionally, operators should monitor the pressure readings before and after the strainer to quickly identify any potential issues that require immediate attention.

Tips: Ensure that you have the right tools on hand for strainer maintenance, such as replacement gaskets and cleaning brushes. Implement a maintenance log to track the cleaning schedule and any changes in pressure readings. This documentation can help predict when the strainer should next be serviced and aid in troubleshooting performance issues before they escalate. Regular training for personnel on Y Type strainer care and upkeep also enhances operational efficiency and minimizes downtime.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.