Understanding check valves is critical for maintaining efficient fluid control across a variety of industrial applications. As a fundamental component in piping systems, check valves ensure the unidirectional flow of liquids and gases, preventing backflow that can lead to system failures and costly downtimes. According to a report by MarketsandMarkets, the global check valve market is projected to reach $5.3 billion by 2024, driven by the increasing demand for fluid control systems in sectors such as oil and gas, water treatment, and power generation.

Industry experts emphasize the importance of these valves in ensuring system integrity. Dr. Emily Carter, a prominent fluid dynamics engineer and author of the influential book "Valves in Process Design," states, "Understanding the operational principles of check valves is essential for any engineering design involving fluid dynamics." This insight resonates within the industry, where effective fluid control directly impacts operational efficiency, safety, and regulatory compliance.

Moreover, as industries continue to evolve with advancements in technology and stricter environmental regulations, the role of check valves becomes even more critical. Proper selection, installation, and maintenance of check valves can significantly enhance system performance and reduce the risk of leakage or failure, underscoring the necessity for professionals to have a comprehensive understanding of this vital component.

Check valves play a crucial role in ensuring efficient fluid control within various systems. These devices are designed to allow fluid flow in one direction while preventing backflow, which can lead to significant operational issues and inefficiencies. According to a report by the U.S. Department of Energy, improper fluid control and backflow incidents account for up to 30% of energy losses in industrial fluid systems. Therefore, understanding the purpose and function of check valves is essential for optimizing fluid dynamics, particularly in applications where maintaining consistent pressure and flow is critical.

In fluid systems, check valves serve multiple purposes beyond just preventing backflow. They help maintain the integrity of the system by protecting pumps and other equipment from damage that can arise from reversed flow. The Fluid Controls Institute estimates that the installation of check valves can enhance system reliability by up to 50%, thereby reducing maintenance costs and downtime. Moreover, they contribute to energy efficiency by minimizing the workload on pumps, which leads to reduced operational costs. With fluid systems becoming increasingly complex, the need for proper understanding and deployment of check valves cannot be overstated, making them essential components for any fluid management strategy.

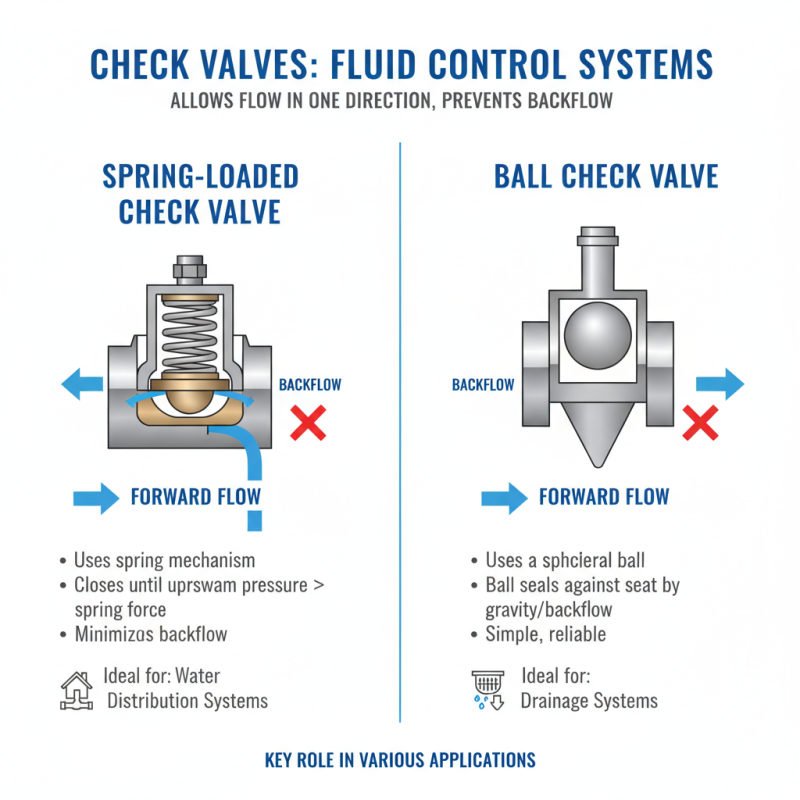

Check valves play a vital role in fluid control systems by allowing flow in one direction while preventing backflow. There are several types of check valves, each designed for specific applications. The two most common types are spring-loaded check valves and ball check valves. Spring-loaded check valves use a spring mechanism to keep the valve closed until the upstream pressure exceeds the spring force, making them ideal for applications where backflow must be minimized, such as in water distribution systems. On the other hand, ball check valves utilize a ball that rests against a seat, sealing off backflow. They are often used in drainage systems where gravity helps to push the ball away and allows fluid to flow through.

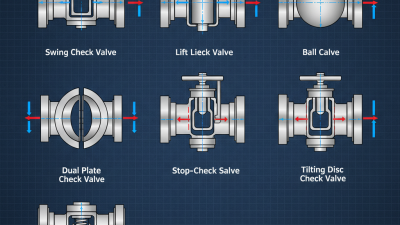

In addition to the commonly used types, there are also lift check valves and diaphragm check valves. Lift check valves have a disc that rises to permit flow and drops to block it, commonly seen in steam and gas applications where pressure variations are frequent. Diaphragm check valves use a flexible diaphragm as a sealing element, making them suitable for sensitive applications such as in the pharmaceutical industry, where contamination must be avoided. Each type of check valve serves a unique purpose and is essential for ensuring efficient fluid control across various industries, from water treatment to manufacturing processes.

Check valves play a crucial role in enhancing system efficiency across various fluid control applications. According to a report by Global Market Insights, the global check valve market is projected to reach over $8 billion by 2026, driven largely by the increasing demand for efficient fluid management systems. These valves allow fluid to flow in one direction while preventing backflow, ensuring that systems operate seamlessly and reducing the risk of flow-related failures. By incorporating check valves into fluid systems, industries can minimize operational disruptions and enhance overall performance.

The importance of check valves is further underscored by a study from the American Society of Mechanical Engineers (ASME), which highlights that improperly functioning or absent check valves can lead to significant energy losses—estimated at up to 20% in some cases. The strategic implementation of check valves helps maintain optimal pressure levels and flow rates, thereby contributing to energy efficiency and reducing operational costs. Furthermore, using check valves can mitigate wear and tear on other components of the system, extending their lifespan and reducing the frequency of maintenance interventions. Collectively, these factors not only optimize the flow of fluids but also ensure the reliability and longevity of the entire fluid control system.

Check valves play a critical role in fluid control systems by ensuring that fluid flows in one direction while preventing backflow. However, despite their importance, these valves can encounter several common issues that can affect their efficiency and overall performance. According to a report by the Fluid Control Institute, approximately 30% of valve failures are attributed to wear and tear caused by improper maintenance and operational stresses. Regular inspections and maintenance practices are essential to mitigate these problems, ensuring that check valves function correctly and prolonging their service life.

One of the most common issues with check valves is sealing failure, which can stem from debris accumulation, corrosion, or thermal cycling. This failure can lead to leaks or backflow, potentially causing significant disruptions in fluid systems. The American Society of Mechanical Engineers (ASME) states that implementing a routine maintenance schedule that includes cleaning and inspecting check valves can reduce the risk of failures by up to 40%. Furthermore, it is crucial to choose the appropriate materials for check valves based on the specific fluid characteristics, as unsuitable material can exacerbate wear and damage over time. Proper training for maintenance personnel on the nuances of valve operation and management is equally important to ensure the longevity and efficiency of check valves in any fluid control system.

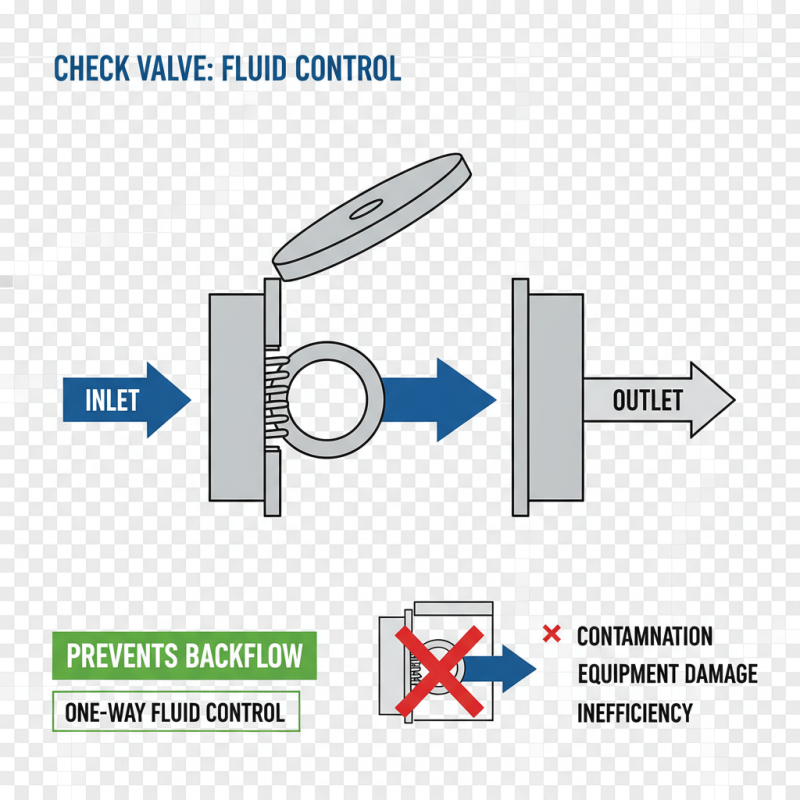

Check valves play a crucial role in fluid control systems by ensuring that fluids flow in a designated direction, thereby preventing backflow. Backflow can lead to a range of issues, including contamination of clean water supplies, damage to equipment, and inefficiencies in process systems. The primary function of a check valve is to act as a one-way gate; it opens to allow flow through when pressure from upstream is sufficient and closes automatically when that pressure decreases, effectively blocking reverse flow.

In many applications, such as water distribution, chemical processing, and HVAC systems, check valves are essential for maintaining system integrity. They help safeguard against potential damage that can arise when fluids reverse direction unexpectedly. Furthermore, the incorporation of check valves contributes to the efficiency of the overall system by maintaining the desired pressure levels and preventing the system from having to work harder to compensate for any backflow-related disruptions. As such, understanding the operational principles and applications of check valves is fundamental for any professional involved in fluid control and management.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.