As industries continue to evolve in response to technological advancements and environmental considerations, the demand for efficient valve solutions has never been greater. In 2025, the focus will shift towards innovative designs and materials that not only enhance performance but also support sustainability initiatives. These valve solutions are critical in various sectors including oil and gas, water treatment, and manufacturing, where precision and reliability are paramount to operational success.

Understanding the core trends and developments in valve technology will empower businesses to make informed decisions that optimize efficiency and reduce costs. The pursuit of top valve solutions involves examining aspects such as material selection, automation integration, and predictive maintenance strategies. By embracing these cutting-edge approaches, industries can achieve greater system reliability and lower downtime, driving overall productivity to new heights.

In this article, we will explore the key valve solutions set to define the landscape for 2025, providing insights and guidelines necessary for organizations to stay ahead of the curve. Whether it’s through smart technology or innovative design, the future of valve solutions promises to unlock unprecedented levels of performance and efficiency across diverse applications.

As we approach 2025, the landscape of valve technologies is set to transform significantly, driving efficiency in various industrial applications. One of the leading advancements is the integration of smart valve technologies, which utilize IoT capabilities to provide real-time monitoring and data analytics. These smart valves enable operators to optimize system performance, reduce downtime, and anticipate maintenance needs, ensuring smoother operations and enhanced productivity. The ability to remotely control and adjust valves in response to fluctuating conditions is especially crucial in sectors like oil and gas, water treatment, and manufacturing.

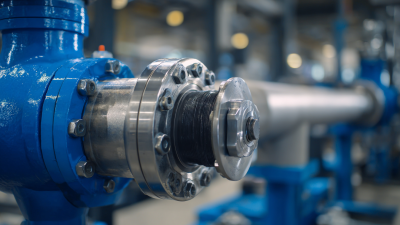

Another emerging trend is the development of high-performance materials for valve construction. Innovative materials such as advanced polymers and composites are enhancing the durability and resistance of valves, making them suitable for extreme conditions and corrosive environments. These materials not only increase the lifespan of the valves but also reduce maintenance costs and improve safety. Furthermore, the adoption of 3D printing technology allows for custom valve designs, enabling quicker production times and tailored solutions for specific applications, thereby maximizing efficiency and performance. As industries continue to seek ways to improve operational efficiency, these valve technologies are poised to play a pivotal role in shaping the future of fluid control systems.

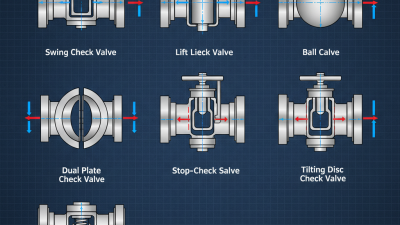

When selecting valves for optimal performance in 2025, several key features come into play. First and foremost, materials and construction quality are essential. Valves should be made from durable materials that can withstand high pressure and temperature variations while offering resistance to corrosion and wear. Moreover, the design of the valve, whether it's a globe, ball, or butterfly type, should align with the specific application to ensure maximum efficiency.

Another critical aspect is the valve's operational mechanics, including response time and ease of installation. Quick-acting valves that can be actuated reliably are necessary for maintaining process control. Additionally, ease of maintenance features, such as self-cleaning designs or modular components, can significantly reduce downtime and maintenance costs. Integrating smart technology, such as sensors and IoT capabilities, can further enhance performance by enabling real-time monitoring and predictive maintenance, ensuring the valve operates optimally at all times.

Considering these key features will help in making informed decisions when selecting valves, leading to improved system efficiency and reliability in diverse applications across various industries. Proper assessment and selection can ultimately drive better performance outcomes and meet the growing demands of modern operations.

As we look toward 2025, sustainability is becoming a key driver in valve selection across various industries. Companies are increasingly prioritizing eco-friendly solutions that not only reduce environmental impact but also enhance operational efficiency. According to a recent report by the International Energy Agency, implementing sustainable practices in industrial operations could lead to a 20-30% reduction in energy consumption. This shift is prompting manufacturers to focus on valves that comply with green standards, such as those with lower emissions and reduced material waste.

Moreover, the trend toward circular economy principles is influencing how valves are designed and selected. A study published by the World Economic Forum estimates that adopting circular practices in industrial sectors could generate up to $4.5 trillion in economic benefits by 2030. In the context of valve solutions, this means a growing emphasis on materials that can be recycled or repurposed, as well as designs that facilitate easy disassembly and maintenance. This sustainable approach not only meets regulatory requirements but also aligns with the environmental goals of many organizations, ultimately leading to a more resilient and responsible industrial ecosystem.

As technology continues to advance, the integration of smart features in valve design, such as real-time monitoring and predictive maintenance, is expected to further enhance sustainability. Industry reports indicate that companies employing smart technology can achieve a 10-15% decrease in operational costs, which complements their sustainability initiatives. Consequently, valve manufacturers are being urged to innovate, aligning their product offerings with these significant trends to ensure optimal performance in the evolving landscape of 2025.

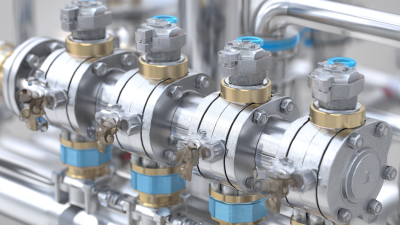

Maintaining valves for optimal performance requires a comprehensive approach that focuses on regular inspections and timely maintenance. One of the key practices is to develop a routine schedule for checking the condition of valves across different systems. This includes assessing seals, gaskets, and other critical components for wear and tear. Addressing minor issues before they escalate can significantly prolong the life of valves and ensure they function effectively when needed.

Another crucial aspect of valve maintenance is ensuring proper lubrication. Using the right type and amount of lubricant can reduce friction and prevent corrosion, which are common causes of valve failure. It's essential to adhere to manufacturer guidelines regarding lubrication frequency and type. Additionally, implementing a monitoring system to track performance parameters can help in identifying early signs of malfunction, allowing for prompt intervention and minimizing downtime. This proactive maintenance strategy not only extends the lifespan of the valves but also enhances overall system reliability.

| Valve Type | Optimal Application | Maintenance Frequency | Expected Lifespan | Best Practices |

|---|---|---|---|---|

| Ball Valve | On/Off Control in Liquid Applications | Every 6 months | 10-20 years | Regular Lubrication, Check for Leaks |

| Gate Valve | Isolation in High-Pressure Systems | Annually | 15-30 years | Inspect Seals and Seats Regularly |

| Globe Valve | Flow Regulation | Every 3 months | 10-15 years | Check for Corrosion, Replace Seals as Needed |

| Check Valve | Prevent Backflow in Pipelines | Every 2 years | 8-15 years | Regular Inspections, Ensure Proper Alignment |

| Butterfly Valve | Flow Control with Low Pressure Drop | Every 6 months | 10-25 years | Keep Actuators Maintained, Check for Wear |

The future of valve design and functionality is poised for significant advancements by 2025, driven by the demand for increased efficiency and sustainability in various industries. As per a report by MarketsandMarkets, the global valve market is projected to reach USD 90 billion by 2025, highlighting the growing emphasis on advanced valve technologies. Innovations such as automated valves and smart sensors are becoming integral, with companies increasingly shifting towards Industry 4.0 standards, which promise enhanced operational efficiency and data-driven decision-making.

One of the most promising innovations in valve technology is the development of smart valves equipped with IoT capabilities. These valves can monitor and control flow in real-time, adapting to changing conditions and providing valuable data to operators. According to a study by Research and Markets, the smart valve segment is expected to grow at a CAGR of 8.5% over the next few years. This trend underscores the industry's shift towards more intelligent systems that not only improve performance but also reduce maintenance costs and downtime, aligning with sustainability goals and regulatory demands.

Moreover, the integration of advanced materials, such as composites and advanced alloys, is revolutionizing valve durability and reliability. These innovations not only extend the lifespan of valves but also enhance their resistance to harsh operating environments, which is particularly critical in the oil and gas, chemical, and water treatment sectors. The combination of smart technology and advanced materials is crucial for organizations looking to achieve optimal performance and ensure adherence to safety standards in their operations by 2025.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.