Understanding the significance of oil valves is crucial in the global energy sector. According to a recent market report, the oil valves market is projected to reach $18 billion by 2025. These components play a vital role in the transportation and management of oil.

Oil valves are integral for ensuring efficient flow and safety in pipelines. Various types serve distinct functions, from controlling pressure to preventing leaks. However, not all valves are created equal. Some may fail under high-stress conditions. This highlights the need for rigorous testing and quality assurance.

As industries innovate, the demand for advanced oil valves continues to rise. Companies must adapt to new technologies while addressing challenges. Understanding the top oil valves can guide decision-making in procurement. Insights from industry reports indicate that investments in quality valves may reduce long-term operational risks. Making informed choices is essential for optimizing performance in oil and gas applications.

In the oil industry, various types of valves play crucial roles in ensuring efficient operations. Among them, the gate valve is essential for stopping and starting the flow. It is often favored for its low flow resistance. In 2022, the global gate valve market reached $3.2 billion, highlighting its significance.

Another essential type is the ball valve. Known for its durability, it can handle high pressures. It also provides a tight seal, minimizing leaks. Research indicates that ball valves account for nearly 30% of the entire valve market. However, their initial cost can be a concern for some operations.

Check valves also find their place. They prevent backflow, preserving system integrity. Yet, many users report that their maintenance can be challenging. This can lead to operational disruptions, prompting reflection on design improvements. Each valve type brings benefits and challenges, making industry knowledge vital for effective selection.

When exploring oil valves, several key features stand out. These valves often use robust materials to withstand high pressure and temperature. Common materials include stainless steel and high-grade polymers. A reliable sealing mechanism is essential. This ensures minimal leakage and maximum safety in oil transport.

Another important aspect is the valve size and connection type. Sizes typically range from small, less than an inch, to larger systems measuring several inches. Connection types vary, allowing for compatibility with various systems. Many valves include manual or automated actuation options, enhancing usability.

While selecting an oil valve, consider the flow rate. It affects the efficiency of oil movement. Many users overlook the importance of regular maintenance. This can potentially lead to failures and costly repairs. Investing time in understanding valve specifications will lead to better operational choices. Always balance performance with budget constraints when making a decision.

| Valve Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Connection Type |

|---|---|---|---|---|

| Ball Valve | Stainless Steel | 1500 | -20 to 200 | Flanged |

| Gate Valve | Carbon Steel | 3000 | -50 to 400 | Welded |

| Globe Valve | Brass | 600 | 0 to 350 | Threaded |

| Check Valve | PVC | 150 | -10 to 140 | Socket |

| Butterfly Valve | Ductile Iron | 200 | -10 to 250 | Flanged |

| Pressure Relief Valve | Stainless Steel | 1500 | -20 to 300 | Flanged |

| Dampener Valve | Aluminum | 600 | -4 to 150 | Threaded |

| Flow Control Valve | Bronze | 300 | 0 to 180 | Flanged |

| Solenoid Valve | Plastic | 150 | -5 to 60 | Quick Connect |

| Pinch Valve | Rubber | 300 | -20 to 150 | Flanged |

Oil valves play a crucial role in many sectors. They control the flow of oil in pipelines, refineries, and storage systems. In the automotive industry, they regulate fuel delivery to engines. This ensures efficient performance. In manufacturing, valves manage the transfer of lubricants, which is vital for machinery operations.

In the energy sector, oil valves help in the exploration and extraction of crude oil. These valves must withstand high pressures and harsh conditions. Their reliability is essential for safety and efficiency. However, improper installation can lead to leaks or failures. This requires careful training and attention to detail.

Meanwhile, in the environmental sector, oil spill prevention is a priority. Valves are designed to minimize risks and control spills. However, not all systems are foolproof. Regular inspections and updates are necessary. This ongoing evaluation often highlights gaps in current practices. Continuous improvement and innovation in oil valve technology remain a challenge.

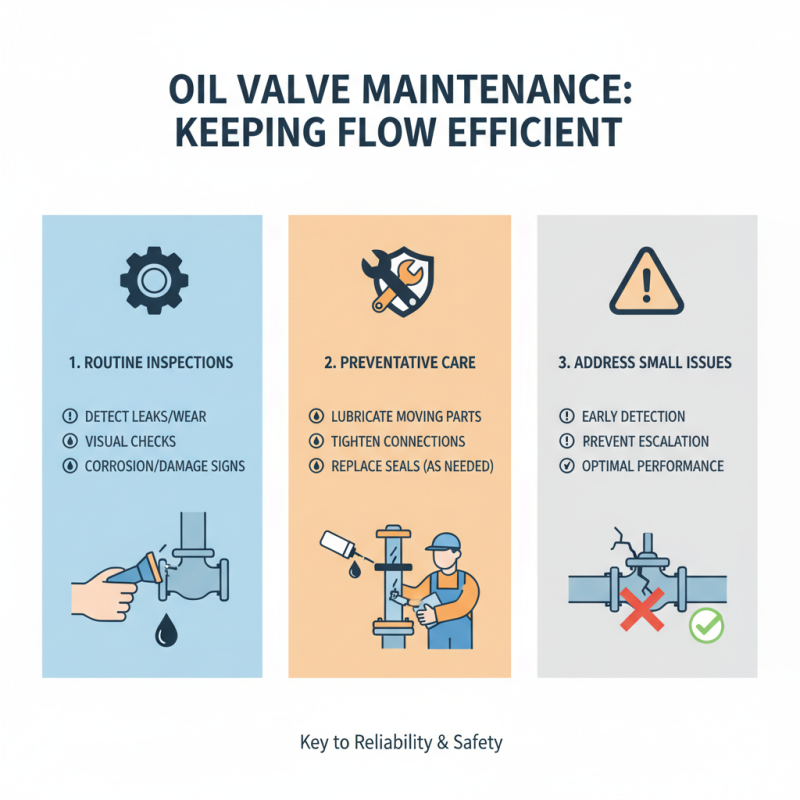

Oil valves play a crucial role in various industries, managing the flow of oil efficiently. To ensure optimal performance, regular maintenance is key. Start with routine inspections to detect leaks or wear. Visual checks can reveal signs of corrosion or damage. It's important not to overlook small issues, as they can escalate into significant problems.

Lubrication is another vital aspect. Proper lubrication minimizes friction and wear. Ensure you use the correct type of lubricant as specified in the guidelines. Over-lubricating can lead to mess and contamination. Pay attention to seals and gaskets; they often wear out and require replacement. A small crack can lead to major leaks.

Additionally, temperature control is essential. Oil valves are sensitive to extreme temperatures. Too hot or too cold can affect their performance. Keep an eye on the operating conditions. Monitoring these factors helps identify when maintenance is necessary. Don't ignore unusual sounds or performance fluctuations. Addressing these early can save time and money later.

In the rapidly evolving world of oil valve technology, several trends are shaping the future. The market is expected to reach $12.5 billion by 2028, according to recent industry reports. This growth is driven by the demand for efficient and durable valves. Smart valve solutions are gaining traction, integrating IoT features for real-time monitoring. These advancements enhance operational efficiency and safety.

Emerging materials are also a focal point. The shift towards lightweight composites is redefining valve design. Reports indicate that valves made from advanced polymers can reduce weight by up to 30%. This change can significantly lower installation and maintenance costs. However, challenges remain. Not all facilities are equipped for new technologies. The transition often requires retraining staff and upgrading infrastructure, which can be daunting.

Lastly, regulatory compliance is tightening. Companies must adapt to stricter environmental standards. This often leads to increased operational complexities. While innovation seems promising, the path forward requires careful consideration. Balancing technology adoption with practical constraints will be crucial for many in the industry.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.