Safety valves are critical components in various industrial systems. They prevent overpressure situations that can lead to equipment failure or catastrophic incidents. According to a report by ResearchAndMarkets, the global safety valve market is projected to reach $5.4 billion by 2027, reflecting the increasing focus on safety standards across industries.

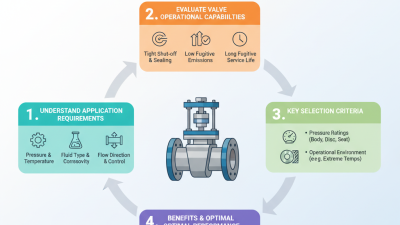

These valves ensure the safe operation of processes in sectors like oil and gas, chemical, and power generation. However, not all safety valves are created equal. Choosing the right safety valve involves understanding its features and applications. Many engineers find themselves facing challenges in selecting the appropriate model for specific needs.

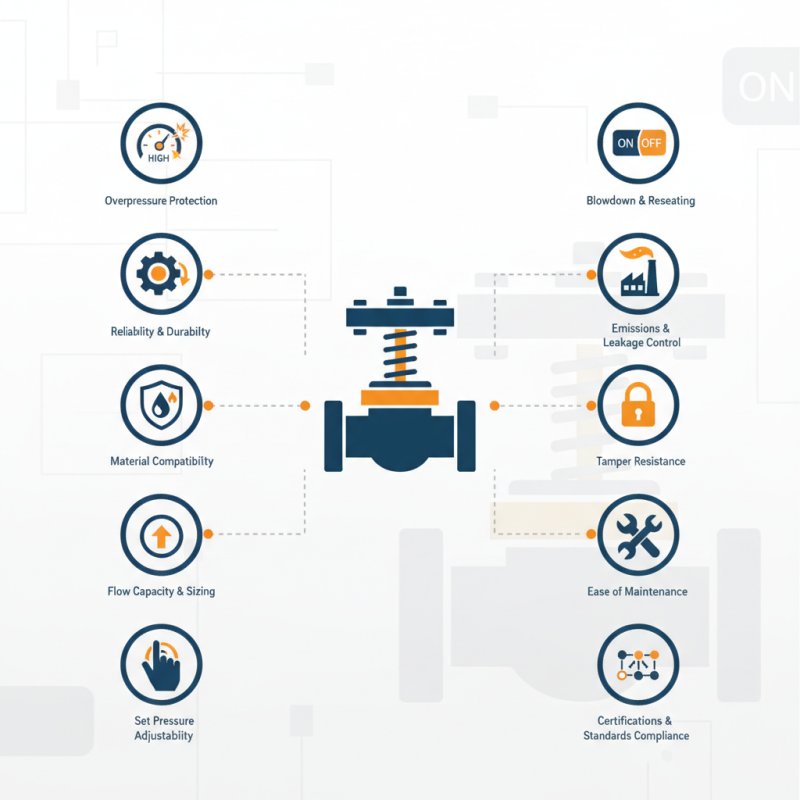

This article delves into the top 10 features of safety valves that every engineer should know. It offers insights that may raise questions about common practices. Are the typical choices always the best? Understanding these features could enhance decision-making and improve safety outcomes.

Safety valves play a crucial role in industrial processes. They ensure systems remain safe under pressure. One key feature is their quick response time. A reliable safety valve should actuate within seconds, preventing overpressure incidents. Another important factor is leak-tightness. A valve that leaks can lead to hazardous situations. Proper sealing mechanisms are vital for safety.

Another essential feature is corrosion resistance. Safety valves often face harsh environments. Using materials that withstand corrosion extends their lifespan. Additionally, ease of maintenance is crucial. Regular checks, repairs, and replacements should be straightforward to ensure continuous operation. Operators often overlook this, leading to potential risks.

Temperature and pressure ratings are also significant. Safety valves should operate well under extreme conditions. However, selecting the right specifications can be challenging. Many industries struggle with this aspect. Finally, an audible alarm feature can enhance safety. It alerts personnel during critical situations. Often, features like this are ignored during installation, potentially compromising safety.

Understanding the pressure settings of safety valves is crucial for their effective operation. Safety valves must activate at specific pressure levels to prevent system failures. According to a report by the American National Standards Institute, improper settings can lead to catastrophic incidents. This highlights the necessity for accurate calibration and constant monitoring.

In practice, setting the pressure too high may allow dangerous build-up of gas or liquid. Conversely, setting it too low could lead to unnecessary operations, wasting energy. Keeping up with industry standards and recommendations is vital. Reports suggest that nearly 30% of industrial accidents result from incorrect pressure settings. Awareness and education can significantly reduce this risk.

Tip: Regular inspections are essential. Ensure that safety valves are regularly tested and calibrated. Investing in training for personnel can decrease human error.

Many facilities overlook the importance of documentation. Keeping track of pressure settings and maintenance history can help in identifying patterns of failure. Analyze data to make informed adjustments. This proactive approach can prevent accidents and enhance overall safety.

| Feature | Description | Importance | Typical Pressure Range (psi) |

|---|---|---|---|

| Set Pressure | The pressure at which the safety valve opens to relieve excess pressure. | Crucial for maintaining system integrity and preventing overpressure scenarios. | 50 - 3000 |

| Materials | Constructed from materials that withstand high pressure and corrosive environments. | Ensures durability and reliability in critical applications. | N/A |

| Sizing | The calculation of valve size based on flow capacity and application requirements. | Correct sizing prevents cavitation and ensures effective operation. | N/A |

| Blowdown | The difference between the set pressure and the pressure at which the valve reseats. | Critical for ensuring the valve closes promptly after relieving pressure. | 10 - 50% |

| Response Time | The time it takes for the valve to open fully after the set pressure is reached. | Fast response is essential in critical applications to prevent damage. | <1 second |

| Test Certification | Certifications indicating compliance with industry standards. | Provides assurance of quality and reliability in performance. | N/A |

| Operating Temperature | The range of temperatures the valve can operate effectively. | Ensures performance in extreme conditions. | -20 to 400°F |

| Maintenance Requirements | Guidelines for routine checks and servicing to ensure proper function. | Regular maintenance prevents unexpected failures. | N/A |

| Mounting Orientation | The position for installing the valve to ensure proper operation. | Correct orientation is vital for effective pressure relief. | N/A |

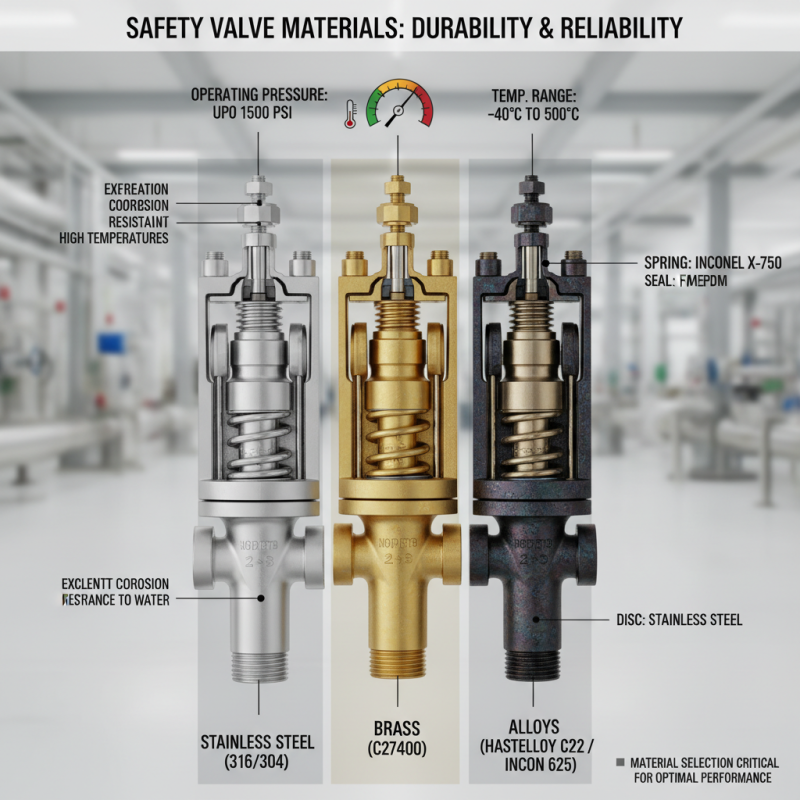

Material selection for safety valves is critical. The right materials ensure both durability and reliability in various applications. Common materials include stainless steel, brass, and various alloys. These choices depend on the operating environment and type of media. Each material has its pros and cons.

For instance, stainless steel is known for corrosion resistance. However, it can be more expensive. Brass is a cost-effective option, often used in low-pressure applications. It may not withstand harsh conditions as well. This selection process can lead to a debate about cost versus longevity. Choosing the wrong material can result in valve failure.

Environmental factors also play a role. Extreme temperatures can affect material performance. High pressures can cause unexpected failures. Continuous testing and inspection are vital to ensure reliability over time. Regular evaluations can uncover potential weaknesses. In the end, thoughtful material selection leads to safer and more efficient operations.

Safety valve certifications and compliance standards are crucial for ensuring the reliability of these safety devices. Each safety valve must meet specific industry regulations. Compliance with standards guarantees functionality under various conditions. It also ensures that the valves will release excess pressure effectively. This prevents potential accidents and equipment damage.

Certifications from recognized bodies can be a game-changer. They establish trust among manufacturers and users alike. When a product is certified, it shows dedication to safety. However, not all safety valves may be certified or compliant. This poses risks that could easily be avoided. A lack of certification can lead to failures in high-pressure systems.

It's essential to verify the credentials of safety valves. Organizations must conduct regular audits to ensure compliance. Inadequate checks can lead to dangerous situations. Poor manufacturing practices can also impact valve performance. Stakeholders should prioritize regular inspections and third-party evaluations. This proactive approach enhances safety and reduces potential hazards in the long run.

Safety valves play a crucial role in maintaining equipment integrity and preventing catastrophic failures. Performance testing is essential to evaluate how effectively these valves operate under various conditions. This process examines aspects like pressure, flow rate, and the valve’s responsiveness. It ensures the valve can open at the right pressure and close promptly when needed.

Testing involves both laboratory assessments and real-world applications. Engineers simulate different scenarios to pinpoint weaknesses. They monitor how the valve behaves under stress. The goal is to identify any flaws that could lead to failure. Sometimes, results reveal unexpected issues that need to be addressed.

These tests can be time-consuming. While they provide valuable insights, variability in results can complicate the evaluation. Each valve design might perform differently. This variability makes it crucial for manufacturers to refine their testing protocols continually. Relying on old data can lead to misconceptions about valve performance. Continuous improvement is essential in this field.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.