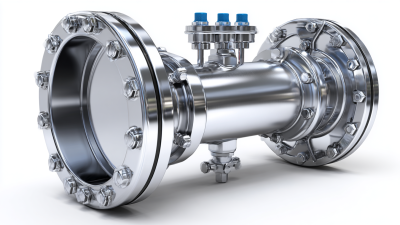

Check valves play a crucial role in various fluid control systems, ensuring that flow occurs in the desired direction while preventing backflow that can compromise system integrity. Understanding the different types of check valves is essential for engineers, technicians, and anyone involved in fluid mechanics. In this article, we will explore the top seven check valve types that are vital for optimal flow control, helping you make informed decisions for your specific applications.

From simple designs to more complex configurations, each check valve type offers unique advantages and is suited for particular operational conditions. Whether you are dealing with industrial processes, residential plumbing, or HVAC systems, selecting the right check valve can significantly impact efficiency, reliability, and safety. As we delve into these seven check valve types, we will highlight their functionality, applications, and key features to enhance your understanding and application of these critical components in your fluid systems.

Check valves are critical components in various fluid systems, ensuring that flow is maintained in one direction and preventing backflow. Familiarity with the types of check valves can significantly enhance flow management across various applications. According to a recent industry report by Research and Markets, the global check valve market is projected to reach $5.8 billion by 2027, highlighting the growing significance of effective flow control in sectors such as water management, oil and gas, and chemical processing.

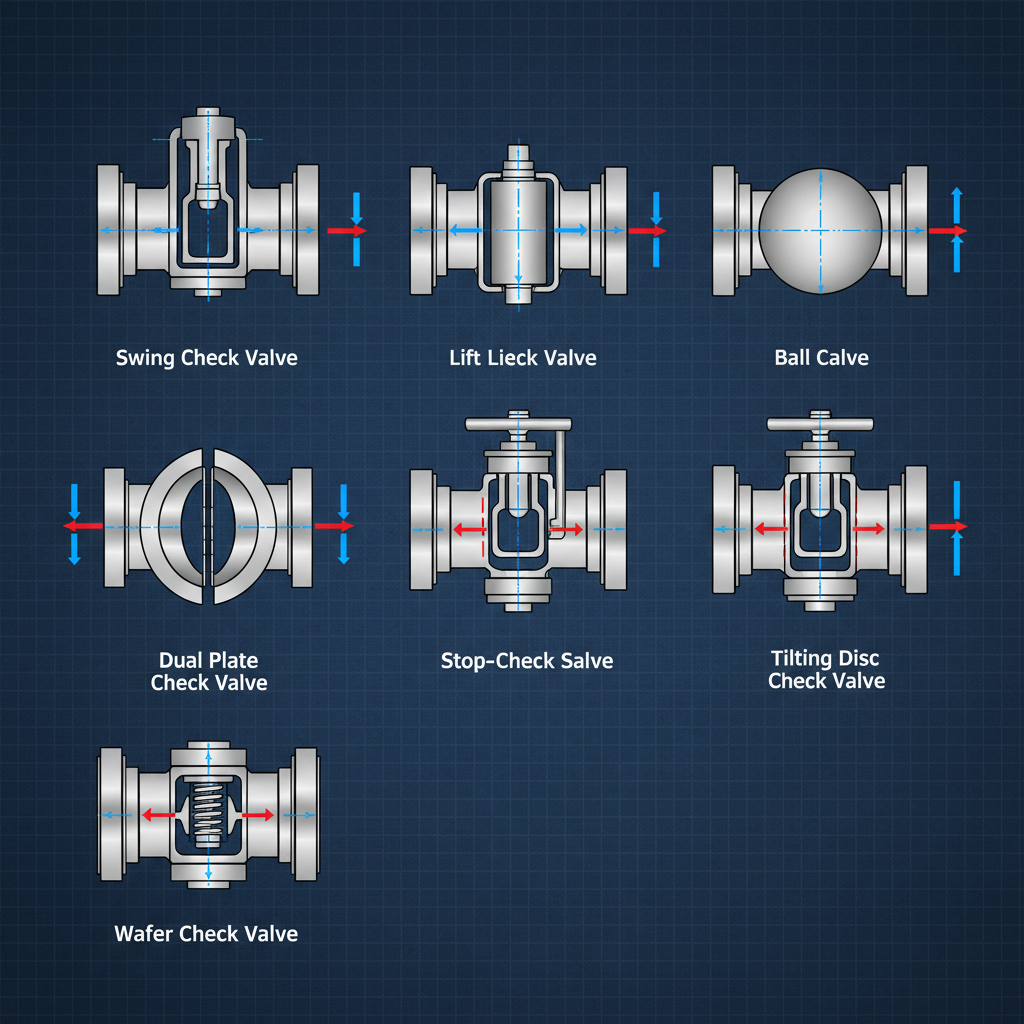

Understanding the different types of check valves—such as swing, lift, and ball check valves—can assist engineers and operators in selecting the most suitable valve for their specific applications. For instance, swing check valves are often used in larger pipelines and provide a robust defense against backflow, while lift check valves are favored for their compact size and efficiency in smaller systems. As noted in a study from the American Society of Mechanical Engineers (ASME), improperly selected check valves can lead to significant energy losses, with some estimates suggesting up to 20% inefficiency in fluid systems. Therefore, a solid grasp of check valve types and their operational principles is essential for optimal flow management in any industrial setting.

| Check Valve Type | Description | Applications | Advantages |

|---|---|---|---|

| Swing Check Valve | Uses a disc to control flow and prevent backflow. | Water supply systems, HVAC. | Simple design, low cost. |

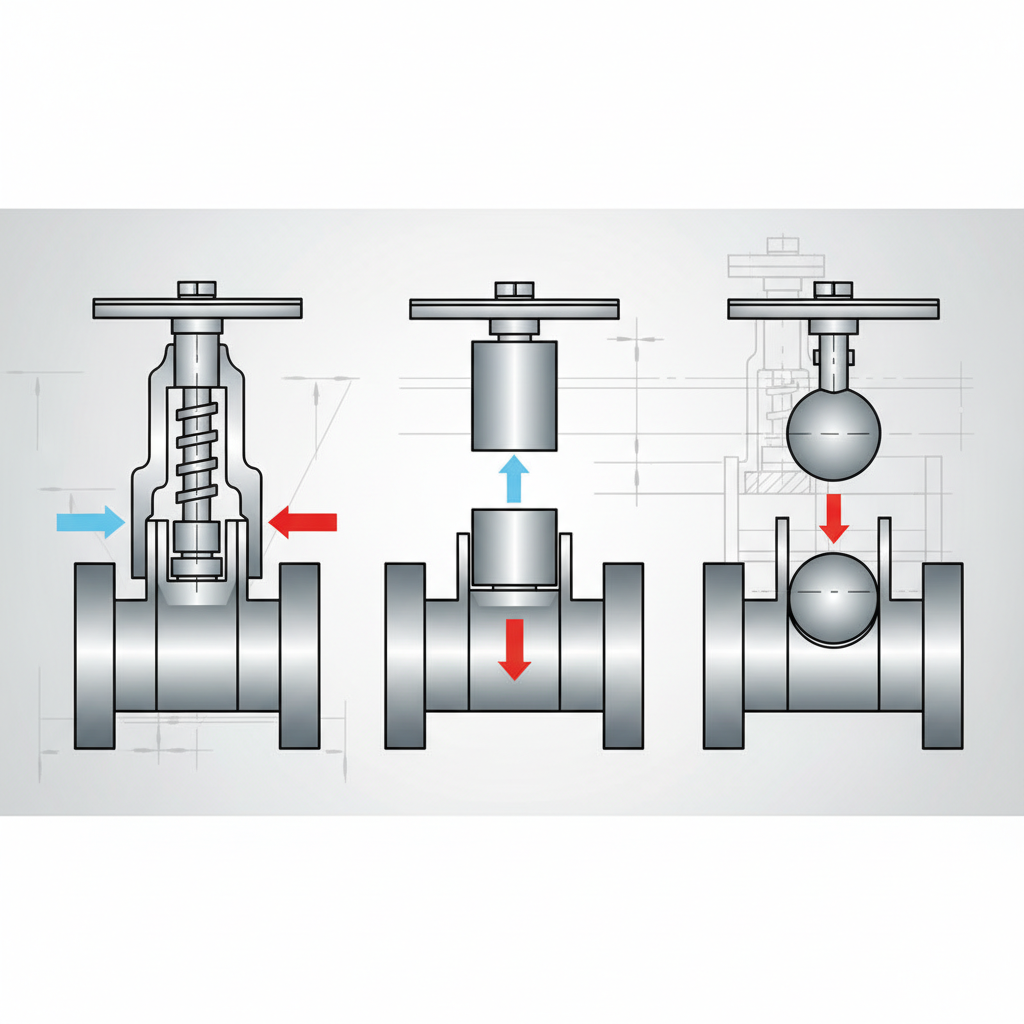

| Lift Check Valve | Uses a disc that moves up and down to allow flow in one direction. | Pumping systems, oil and gas pipelines. | Better sealing than swing valves. |

| Dual Plate Check Valve | Features two plates that open and close based on flow direction. | Marine applications, wastewater treatment. | Compact design, less fluid resistance. |

| Ball Check Valve | Uses a ball to block reverse flow. | Chemical processing, stormwater management. | High reliability, minimal wear. |

| Diaphragm Check Valve | Utilizes a flexible diaphragm to prevent backflow. | Water treatment, pharmaceutical applications. | Suitable for viscous fluids, offers tight sealing. |

| Stop Check Valve | Combines the functionality of a stop valve and a check valve. | Large pipeline systems, irrigation. | Prevents backflow while allowing easy shutoff. |

| Spring Loaded Check Valve | Uses a spring mechanism to assist closing the valve. | Pipeline systems with high flow velocities. | Fast response time, reduces water hammer. |

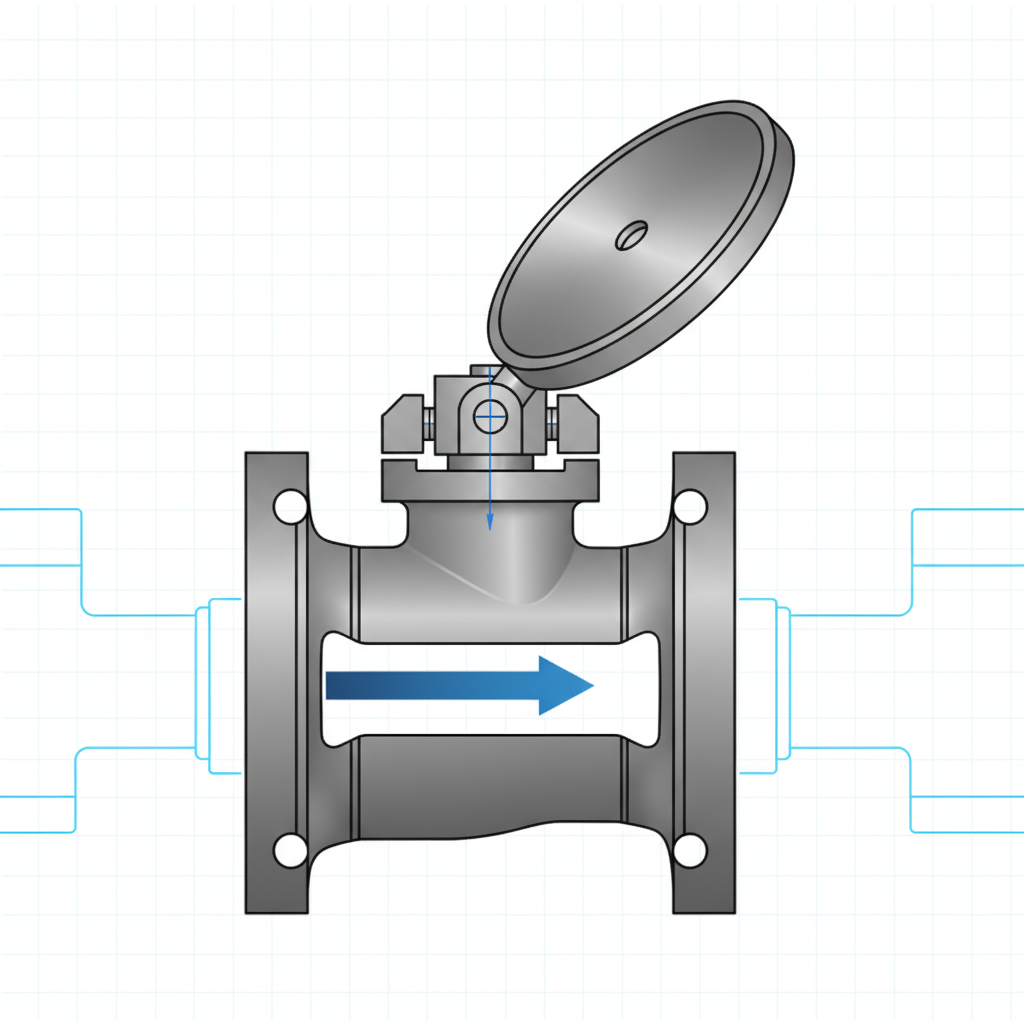

When selecting the appropriate check valve type for optimal flow control, it's crucial to consider the specific features each type offers. Swing check valves are ideal for applications where backflow prevention is critical, as they utilize a disc that swings on a hinge, allowing for unobstructed fluid flow in one direction. Their simple design and reliability make them suitable for a wide range of fluids, including water and low-viscosity liquids.

Another popular type is the spring check valve, which incorporates a spring mechanism to facilitate closure. This design provides quick response times and is especially effective in high-pressure applications, as it minimizes the risk of water hammer. Additionally, dual-disc check valves present a compact option that reduces pressure loss due to their lighter weight and smaller size, making them an excellent choice for pipelines with limited space while ensuring effective flow regulation in varied environments. Understanding these key features allows for better decision-making in selecting the right check valve type for your specific application needs.

When selecting the appropriate check valve for specific flow requirements, it is essential to understand the distinct characteristics of various valve types. Each type, whether it be swing, lift, or ball check valves, operates under different principles and applications. For instance, swing check valves are ideal for horizontal piping systems where backflow prevention is crucial, while lift check valves excel in vertical applications due to their design that allows fluid to flow both ways without significant pressure loss.

Additionally, factors such as the fluid's viscosity, temperature, and potential for solids presence must be considered. A ball check valve, known for its reliability and low-pressure drop, may be optimal for clean fluids but could be unsuitable for slurries or fluids containing particulates. Understanding these nuances ensures that the selected check valve not only meets the necessary operational standards but also promotes effective and efficient flow control in the system.

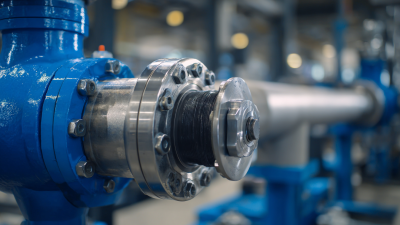

Check valves are essential components in a variety of industries, ensuring unidirectional flow and preventing backflow in piping systems. In the oil and gas sector, for example, the global check valve market was valued at approximately $3.1 billion in 2022, with projections estimating it will reach $4.6 billion by 2030. This growth is driven by increasing investments in pipeline infrastructure and rising energy demands, emphasizing the critical role of check valves in maintaining safe and efficient operations.

In water management, check valves are employed to protect pumps from backflow, which can cause significant damage and operational inefficiency. According to a recent report from the Water Research Foundation, improper backflow management can lead to contamination of water sources, costing municipalities millions annually in remediation efforts. Additionally, the chemical processing industry leverages check valves to ensure that hazardous chemicals flow in the intended direction, safeguarding personnel and equipment. These diverse applications highlight the versatility of check valves across industries and underscore their importance in optimizing flow control while mitigating risks associated with backflow.

Proper maintenance of check valves is crucial for ensuring their longevity and optimal performance in flow control systems. According to a study by the International Journal of Valves and Actuators, improperly maintained check valves can lead to significant inefficiencies, resulting in a potential flow reduction of up to 25%. Regular inspections should be prioritized to check for leaks, wear, and corrosion, which are common issues arising from prolonged use. Keeping the valves clean and free from debris can facilitate better operation, as contaminants can lead to blockages and system failures.

To extend the lifespan of check valves, it is essential to follow best practices for maintenance. The American Society of Mechanical Engineers (ASME) recommends performing a detailed evaluation at least once a year, including the disassembly and cleaning of the valve body. Additionally, applying appropriate lubricants can minimize friction and wear on the valve components, ensuring smoother operation. Monitoring the valve's operational environment—like pressure levels and temperature variations—can help in making informed adjustments and repairs as necessary, significantly reducing the risk of premature failure.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.