Swing valves are essential components in various industrial settings, playing a critical role in fluid control and management. Their design allows for efficient flow regulation, making them ideal for applications that require reliable performance and durability. In an era where operational efficiency and safety are paramount, understanding the advantages of implementing swing valves can be invaluable for industry professionals.

The versatility and functionality of swing valves make them suitable for a wide range of systems, from water treatment facilities to oil and gas pipelines. Their ability to withstand high pressures and temperatures, combined with low maintenance requirements, contributes to enhanced operational reliability. Furthermore, these valves can easily accommodate changes in flow direction, ensuring seamless integration into existing workflows.

As industries continue to evolve, the demand for reliable and efficient flow control solutions increases. This article will explore the top ten benefits of utilizing swing valves in industrial applications, highlighting their roles in optimizing processes, improving safety, and ensuring long-term cost-effectiveness. By delving into these advantages, we aim to provide insights that can help businesses leverage swing valves to enhance their operations and achieve greater efficiency.

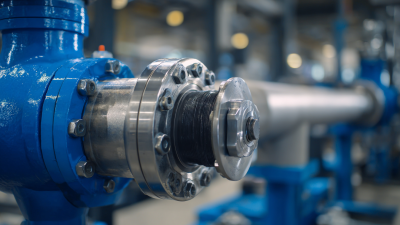

Swing valves are essential components in many industrial applications, providing reliable flow control in piping systems. These valves operate using a disc that swings on a hinge, allowing them to open and close efficiently. According to a report by the Global Valve Market Analysis, swing valves can handle large volumes of fluids with minimal pressure loss, making them ideal for use in applications such as water treatment plants, oil and gas industries, and chemical processing facilities. Their design not only promotes smooth flow but also reduces turbulence, which is critical for maintaining fluid integrity and system efficiency.

The functionality of swing valves is largely attributed to their simple yet effective design. When the differential pressure across the valve exceeds a certain threshold, the valve opens, directing flow through the system. This design minimizes wear and tear, extending the lifecycle of the valve and reducing maintenance costs. A study by the American Society of Mechanical Engineers highlighted that operational efficiency can be enhanced by implementing swing valves in systems requiring high flow rates, as they offer rapid response times with low energy consumption. By understanding how swing valves operate and their benefits, industries can optimize their processes, leading to greater efficiency and cost savings.

Swing valves offer several key advantages in industrial systems, making them a preferred choice in various applications. One of the main benefits is their effective flow regulation capability. The design of swing valves allows for minimal pressure drop and efficient flow control, which is essential in maintaining optimal operational efficiency. This attribute is particularly valuable in processes where precise flow management is crucial, as it helps to reduce energy consumption and enhance system performance.

Another significant advantage of using swing valves is their reliability and durability. Constructed to withstand harsh conditions, swing valves can handle high pressure and temperature fluctuations, making them suitable for demanding industrial environments. Additionally, their simple yet robust design contributes to ease of maintenance, leading to reduced downtime and operational costs. The ability to maintain performance over time ensures that industrial systems remain efficient and reliable, minimizing interruptions in production. These benefits underline the importance of swing valves in ensuring the smooth operation of industrial processes.

| Benefit | Description | Application Example |

|---|---|---|

| 1. High Flow Capacity | Swing valves provide a larger flow area, allowing for efficient fluid transfer. | Water treatment plants |

| 2. Minimal Pressure Drop | They maintain low pressure loss during operation, enhancing system efficiency. | Oil and gas pipelines |

| 3. Robust Construction | Built to withstand high pressure and temperature, ensuring durability. | Chemical processing |

| 4. Easy Operation | Simple design allows for quick opening and closing, improving handling. | HVAC systems |

| 5. Low Maintenance | Fewer moving parts reduce the need for frequent maintenance. | Water distribution systems |

| 6. Versatile Applications | Can be used in various types of fluids, including gases and liquids. | Pharmaceutical manufacturing |

| 7. Cost-Effective | Competitive pricing compared to other valve types without sacrificing quality. | Food processing industries |

| 8. Reliability | Proven track record of consistent performance in industrial systems. | Power generation |

| 9. Compact Design | Space-saving design suitable for limited installation areas. | Mining operations |

| 10. Wide Size Range | Available in various sizes to fit different system requirements. | Irrigation systems |

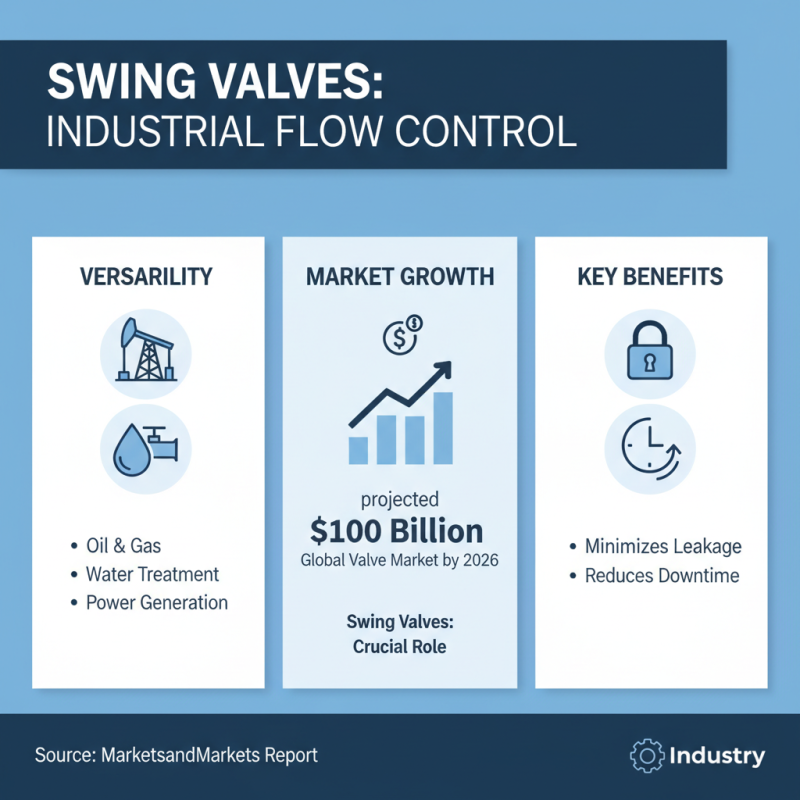

Swing valves are widely used across various industrial applications due to their efficient flow control and robust design. Their versatility is evident in sectors such as oil and gas, water treatment, and power generation. According to a report by MarketsandMarkets, the global valve market is projected to reach $100 billion by 2026, with swing valves playing a crucial role in this growth. In the oil and gas industry, for instance, swing valves are essential for managing the flow of crude oil and natural gas, providing a reliable mechanism that minimizes leakage risks and reduces downtime.

In the water treatment sector, swing valves facilitate the management of water flow in filtration systems and wastewater management processes. A study conducted by the Water Environment Federation indicates that employing swing valves can enhance system efficiency by up to 15%. The simplicity of their design allows for easy maintenance and durability, making them an ideal choice for handling various liquids and gases under diverse pressure conditions. Furthermore, their ability to operate silently adds to their appeal in environments where noise reduction is critical, such as in residential zones and sensitive areas around industrial plants.

Swing valves are a favored choice in various industrial applications due to their unique advantages over other valve types. One notable difference is their flow efficiency. According to a recent report by the American Society of Mechanical Engineers (ASME), swing valves often exhibit lower pressure drops than globe or ball valves, which can lead to reduced energy consumption and improved system performance. This is particularly beneficial in applications requiring high flow rates, as their design allows for a smoother path for the fluid, minimizing turbulence.

Another point of comparison is their durability and maintenance. Swing valves tend to have fewer moving parts compared to other designs like gate or ball valves, translating to lower wear over time. A study published in the Journal of Pressure Vessel Technology showed that swing valves can last up to 30% longer under similar conditions, thus reducing the frequency and costs associated with replacements and repairs. However, it is crucial to ensure that the installation and maintenance protocols are followed meticulously to optimize their lifespan.

Tips: Regular maintenance checks are essential to ensure the optimum performance of swing valves. Simple practices such as inspecting for leaks and ensuring proper alignment can significantly extend their operational life. Additionally, considering the specific fluid type and temperature during selection can further enhance efficiency. Always refer to industry reports and standards to guide your decision-making process appropriately.

When utilizing swing valves in industrial applications, maintenance plays a crucial role in ensuring optimal performance and longevity. Regular inspection of swing valves for signs of wear, such as cracks or corrosion, is vital. Operators should check the valve seals and seating surfaces to make sure they are functioning properly, as damaged components can lead to leaks and inefficiency. Keeping a detailed maintenance log helps track the performance and any repairs needed, allowing for a proactive approach to valve upkeep.

Tips for maintaining swing valves include implementing a routine maintenance schedule, which should encompass visual inspections and operational testing. It's important to ensure that the surrounding environment is clean and free from contaminants that could affect valve performance. Additionally, consider the installation conditions; swing valves should be installed in locations that minimize exposure to extreme temperatures and vibrations, which can adversely affect their operation.

Another best practice is to establish clear operational guidelines for valve use. Train personnel on the correct methods for operating swing valves to prevent manual errors that could lead to malfunctions. Encourage prompt reporting of any unusual noises or changes in flow behavior, as these may indicate underlying issues that require immediate attention. By relying on these strategies, industries can maximize the effectiveness and reliability of swing valves in their processes.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.