In the ever-evolving world of gas valves, making an informed decision can be a challenge for both homeowners and industry professionals. As we navigate the complexities of choosing the right valve for specific applications, expert insights prove invaluable. Renowned gas valves expert, Dr. Emily Reed, emphasizes the importance of understanding both functionality and safety when she states, "Selecting the right gas valve is not just about efficiency; it's about ensuring secure and reliable operation in every situation."

As we advance towards 2025, a myriad of options are emerging in the gas valves market, catering to diverse needs and preferences. This ultimate guide aims to streamline your decision-making process by highlighting the top ten gas valves available today. From durability and performance to advanced features, we will explore what sets these valves apart and how they can meet the demands of various settings.

Join us as we delve into the critical factors that influence your choice and showcase the best options in the gas valves industry. With expert recommendations and a clear understanding of the market trends, you'll be equipped to make a choice that not only enhances operational efficiency but also prioritizes safety in your applications.

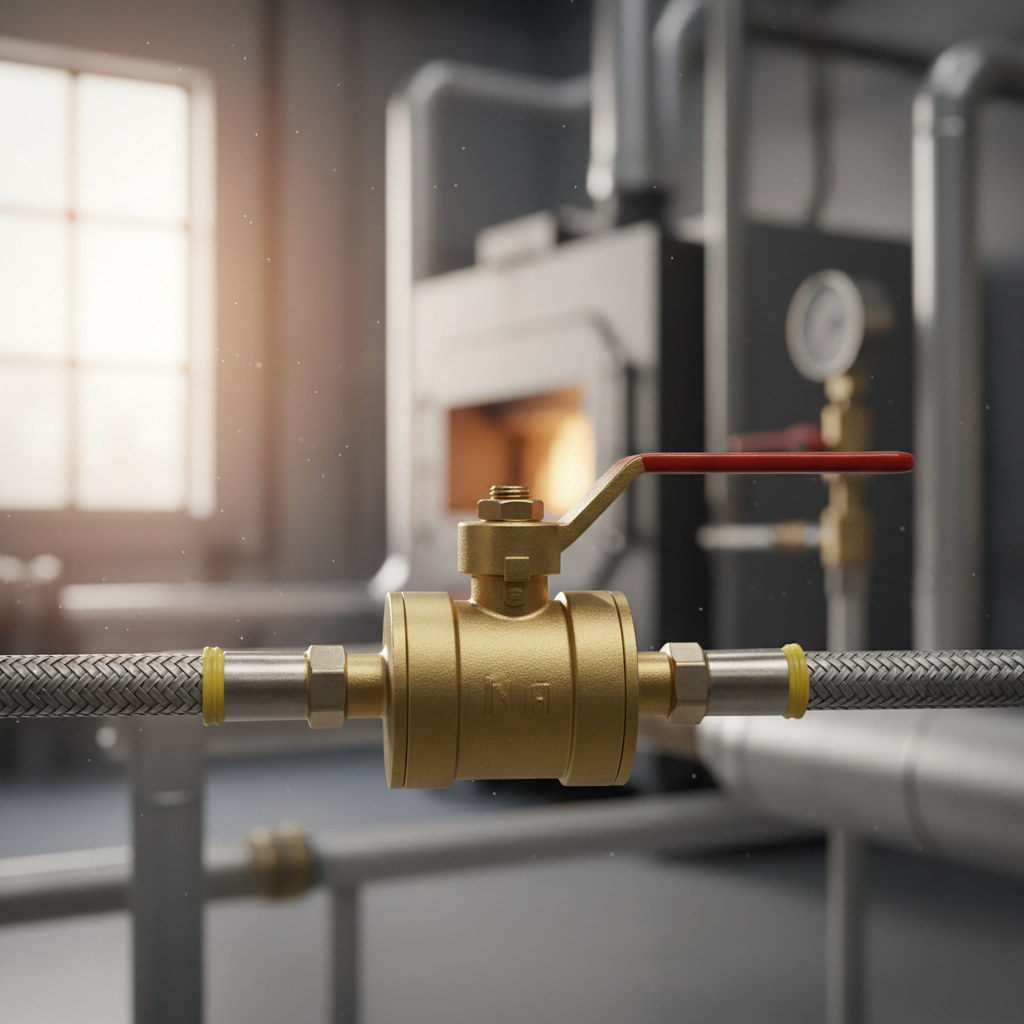

When selecting gas valves, understanding key features is crucial for ensuring safety and efficiency in various applications. One of the first aspects to consider is the valve type. According to the 2022 Gas Equipment Report, ball valves dominate the market due to their reliability and ease of use, accounting for approximately 45% of all gas valve sales. They provide a robust sealing capacity, making them ideal for both residential and industrial settings.

Another important factor is the valve material. Material choice impacts the valve's durability and resistance to corrosion. For example, stainless steel valves are favored for their strength and longevity, especially in environments where exposure to harsh conditions is common. A recent study by the International Gas Union revealed that valves made from high-grade materials can increase operational lifespan by up to 30%, reducing maintenance costs significantly. Ultimately, assessing the right combination of type and material can greatly enhance performance and ensure compliance with regulatory requirements.

When it comes to selecting the best gas valves for commercial or residential applications, reliability and performance are paramount. Industry reports highlight that approximately 30% of gas outages can be traced back to valve failures. Therefore, choosing the right brand can significantly influence both safety and efficiency. Among the many brands available, **Honeywell**, **Parker**, **Emerson**, **Kohler**, and **Fisher** stand out as the top five recommended for their proven track record.

Honeywell is renowned for its innovative designs and durability. Their gas valves are often cited for their ability to minimize leakage, which is crucial for both safety and cost savings. Similarly, Parker's expertise in fluid control systems results in valves that are not only efficient but also easy to install. A recent industry analysis reported that Parker valves have a failure rate of less than 1%, making them a reliable option for high-demand scenarios. Meanwhile, Emerson’s gas valves offer exceptional adaptability to various flow conditions, ensuring optimal performance across diverse applications, backed by a 98% customer satisfaction rating.

When selecting a gas valve, understanding the material types is crucial for ensuring safety and efficiency. Common materials for gas valves include brass, stainless steel, and plastic.

Brass is widely used due to its corrosion resistance and durability, making it ideal for high-pressure applications. Stainless steel offers a higher resistance to extreme temperatures and is often preferred in industrial settings where strength and longevity are paramount. In contrast, plastic valves are lightweight and cost-effective, suitable for low-pressure systems, but may not withstand harsh environments.

Each material has its pros and cons, which can significantly affect the performance of gas appliances. For instance, brass valves are typically more resilient to wear and tear compared to plastic ones but can be heavier and more expensive. Stainless steel, while robust, can also come with a higher price tag. Ultimately, the choice of material should align with the specific needs of the application, balancing factors such as pressure requirements, environmental conditions, and budget constraints. This breakdown not only aids in selecting the right gas valve but also reinforces the importance of quality materials in gas systems for safety and reliability.

When it comes to ensuring optimal gas valve functionality, installation and maintenance are key components that shouldn't be overlooked. Proper installation not only enhances the performance of the gas valve but also contributes to overall safety. Make sure to follow manufacturer guidelines during installation, checking for any leaks after connecting the valve. It’s essential to use the right tools and fittings to prevent any future issues.

Regular maintenance is equally important to keep your gas valve in top shape. Schedule periodic inspections to check for signs of wear and tear, and replace any worn components to avoid malfunctions. Cleaning the valve is crucial; dirt and debris can accumulate over time, impacting its performance. A simple wipe down with a damp cloth can go a long way in maintaining functionality.

Lastly, don’t forget to consult a professional when in doubt. Some gas valve systems can be complex, and having an expert handle installations or repairs can save you time and ensure safety. By following these tips, you can enhance the reliability and safety of your gas valve system for years to come.

| Model | Type | Size (inches) | Pressure Rating (psi) | Material | Applications |

|---|---|---|---|---|---|

| Valve A | Ball Valve | 1/2 | 150 | Brass | Residential |

| Valve B | Gate Valve | 3/4 | 200 | Steel | Commercial |

| Valve C | Check Valve | 1 | 300 | PVC | Industrial |

| Valve D | Butterfly Valve | 2 | 150 | Aluminum | Municipal |

| Valve E | Pressure Relief Valve | 1/4 | 100 | Stainless Steel | Safety Systems |

| Valve F | Solenoid Valve | 3/8 | 150 | Brass | Automated Systems |

| Valve G | Angle Valve | 1 | 250 | Copper | HVAC Systems |

| Valve H | Pilot Valve | 2 | 200 | Plastic | Pressure Control |

| Valve I | Flow Control Valve | 3/4 | 150 | Iron | Fluid Systems |

| Valve J | Diaphragm Valve | 2 | 100 | Teflon | Chemical Processing |

When selecting gas valves, understanding safety standards and certifications is paramount. The International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) set important guidelines that ensure valves are safe and reliable. For instance, ISO 9001 outlines quality management principles critical for manufacturers, while ANSI Z21.21 covers standards specific to gas appliance valves. According to a report by the National Fire Protection Association (NFPA), adhering to these certifications can significantly reduce the risk of gas leaks and related hazards, underscoring the importance of selecting certified products.

Tips: Always check for compliance with local regulations and standards when purchasing gas valves. Look for valves marked with certifications from recognized bodies such as UL (Underwriters Laboratories) or ETL (Intertek), which can provide assurance of safety and performance.

Additionally, consider the materials used in the valve construction. The National Institute of Standards and Technology (NIST) notes that valves made from durable materials like brass or stainless steel can withstand higher pressures and temperatures, enhancing safety. When choosing a valve, evaluate factors such as the intended application, flow rate requirements, and environmental conditions to ensure optimal performance and compliance with safety standards.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.