When it comes to selecting the right flanged butterfly valve for your system, careful consideration is essential. The global valve market is projected to reach $85 billion by 2027, according to a recent report by MarketsandMarkets. Butterfly valves play a crucial role in controlling flow due to their compact design and efficient operation. These valves are widely used across various industries, including oil and gas, water treatment, and power generation.

Understanding your specific application is vital. Factors such as pressure, temperature, and fluid type directly impact valve performance. Inadequate selection may lead to costly failures. A study by Grand View Research indicates that improper valve selection costs industries billions annually. Thus, having a clear grasp of system requirements can prevent performance issues.

Flanged butterfly valves come with different materials and designs, making the selection process daunting. Common materials include stainless steel, ductile iron, and PVC. Each has its advantages and limitations. Customization options can vary greatly among manufacturers. Choosing a quality supplier is not merely a recommendation; it is a necessity to ensure reliability and efficiency in your system.

Flanged butterfly valves are essential components in various systems. Their design allows for efficient flow control while minimizing pressure drops. Understanding how they work is crucial for selecting the appropriate valve for your application. Typically, these valves consist of a disc that rotates to regulate flow. Data from industry reports show that the global butterfly valve market is expected to grow at a CAGR of 5.3% through 2026. This growth indicates an increasing reliance on these valves in sectors like water treatment and oil and gas.

When choosing a flanged butterfly valve, consider the material. Common options include stainless steel, cast iron, and PVC. The working environment can influence your decision. For example, corrosive fluids may require more durable materials. A poorly chosen valve can lead to costly leaks and system failures. A report from the American Society of Mechanical Engineers highlights that improper valve selections can account for 30% of system inefficiencies.

Tips: Always verify the pressure rating. Ensure it meets your system's requirements. Check compatibility with materials in your system. Small details can prevent big issues. It's easy to overlook these factors amid complex specifications. Reflecting on your needs can lead to better choices. Understanding the basics can guide you toward the best flanged butterfly valve for your needs.

This chart illustrates the relative importance of various criteria when selecting a flanged butterfly valve for your system. The dimensions include Diameter, Pressure Rating, Temperature Range, and Material Type, which all play crucial roles in ensuring the selected valve meets operational requirements.

Selecting the right flanged butterfly valve requires a clear understanding of system specifications. One key aspect is pressure rating. According to a recent industry report, most systems operate within 150 to 300 PSI. Validating the pressure requirements is crucial to avoid failures.

Another important factor is temperature tolerance. Valves must withstand the operating range without degrading. The same report indicates that many systems operate effectively between -20°F to 400°F. Therefore, knowing the temperature limits helps ensure reliable performance.

Size and flow rate matter too. Research shows that the valve diameter should match pipe dimensions closely. An improper fit can lead to turbulence. A flow rate mismatch can cause inefficiencies, often exceeding 10% in some cases. Addressing these specifications is vital for long-term system success.

Selecting the right flanged butterfly valve requires careful consideration of material compatibility and environmental factors. The valve's materials must align with the fluid type. For instance, aggressive chemicals may require corrosion-resistant materials. In contrast, water and gases generally have more flexible options. Always research compatibility before making a choice.

Tips: Perform a compatibility test. This small step can prevent costly mistakes. Consider the operating temperature and pressure as well. These factors directly influence material durability.

Environmental conditions also play a crucial role. High humidity, temperature extremes, or exposure to UV light can degrade certain materials. The valve should withstand these factors for optimal performance. Understanding the environment helps in selecting the right valve.

Tips: Assess the surrounding conditions where the valve will be installed. Take detailed notes. This practice may reveal overlooked details impacting durability. Consider future changes in conditions, too, as systems evolve over time.

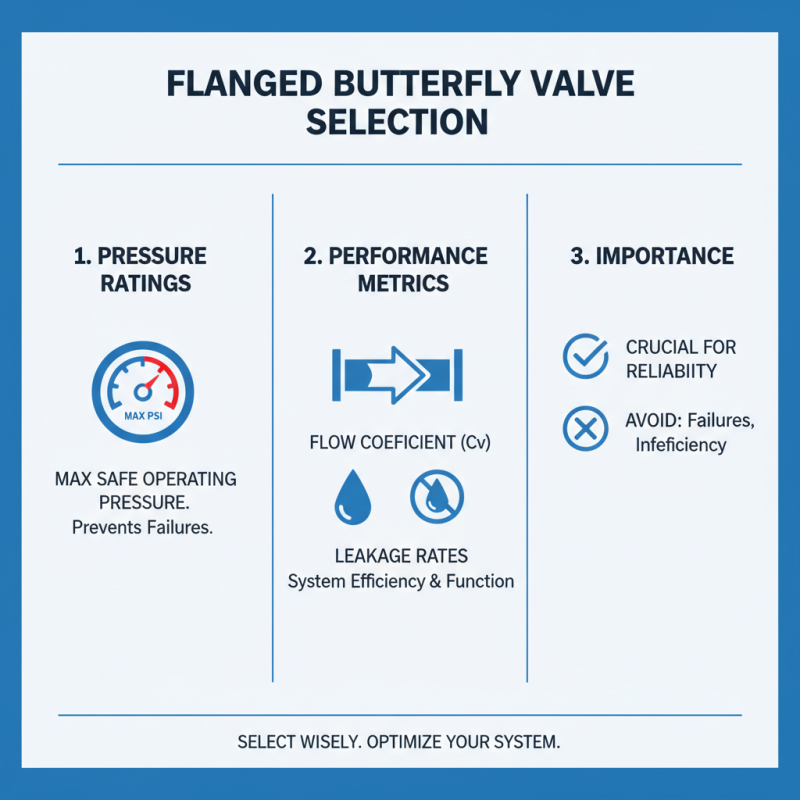

When selecting a flanged butterfly valve, understanding pressure ratings is crucial. These ratings indicate the maximum safe operating pressure for the valve. A valve's performance metrics include factors like flow coefficient and leakage rates. They help determine how well the valve will function in your system. Neglecting these aspects can lead to failures or inefficiencies.

Tip: Always check the valve's pressure rating against your system's requirements. Mismatches can result in costly damages. Consider the medium's nature, too; aggressive fluids may require specialized materials.

Another important metric is the flow coefficient (Cv). This number reflects how much flow a valve can handle. A higher Cv means greater flow capability. But, be wary. A valve with an excessively high Cv may not control flow accurately.

Tip: Evaluate your system's flow conditions. Overestimating flow needs can lead to poor performance. Choose a valve that offers a good balance between capacity and precise control. Taking the time to assess these metrics will enhance your selection process.

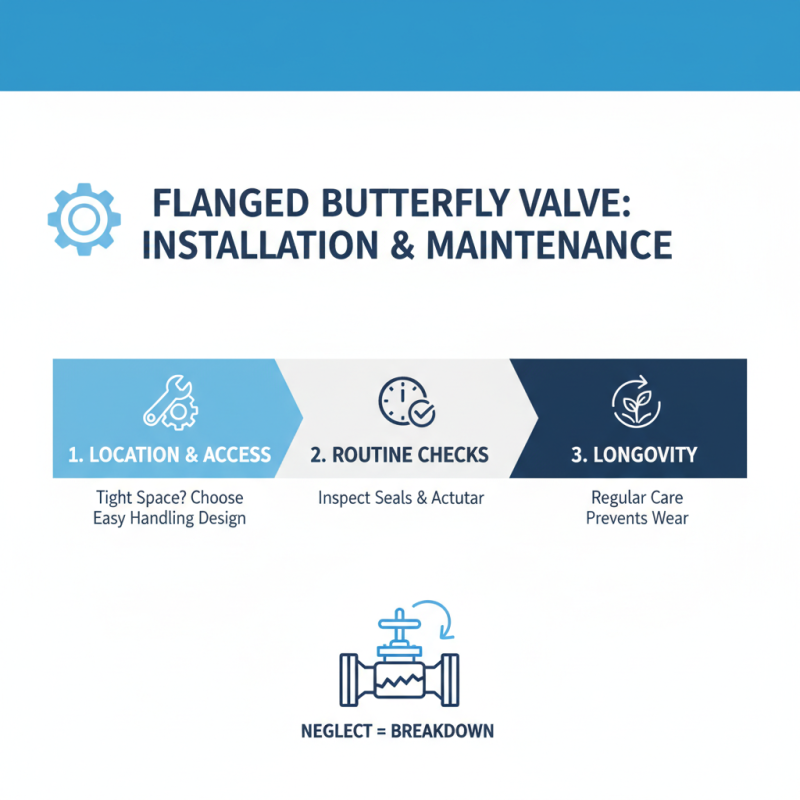

When selecting a flanged butterfly valve, installation and maintenance are crucial. The valve's location affects access for routine checks. If it's in a tight space, consider a design that allows easy handling. Regular maintenance ensures longevity. You want to inspect seals and actuator functions frequently. The valve may fit well initially, but neglect transforms it over time.

Installation must suit your specific system's needs. Valve orientation matters greatly; improperly installed valves may lead to leaks. Ensure you follow the manufacturer's guidelines closely. Use quality gaskets and bolts to minimize issues. Don’t overlook local environmental conditions. They can impact the valve’s performance and lifespan.

Evaluate maintenance conditions regularly. Setting a schedule can keep the valve operational. Sometimes, a valve looks fine on the outside, but internal damage lurks. Be diligent. The wrong maintenance approach might cause unexpected failures. A minor oversight can lead to significant repairs down the line. Prioritize proactive strategies to maintain the valve efficiently.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.