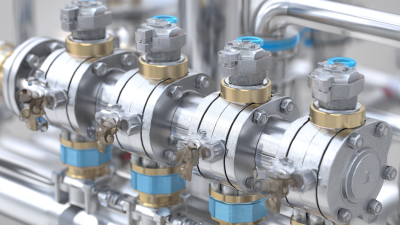

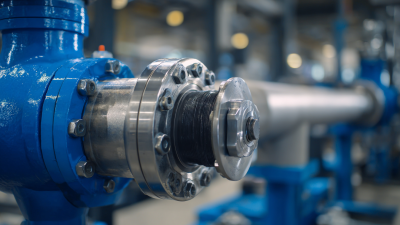

In recent years, the industrial automation landscape has evolved dramatically, with valve vendors playing a crucial role in enhancing operational efficiency and reliability across various sectors. According to a report by MarketsandMarkets, the global industrial valve market is projected to reach USD 80.24 billion by 2025, growing at a CAGR of 4.5%. This growth underscores the critical importance of choosing the right valve vendors to meet the increasing demand for automation solutions that not only streamline processes but also improve overall system performance. As industries strive to optimize their operations and reduce downtime, the role of valve vendors has expanded, providing advanced technologies such as smart valves and IoT integration. These innovations not only facilitate real-time monitoring and control but also promote energy efficiency and sustainability. Therefore, understanding the impact of valve vendors in modern industrial automation is essential for businesses aiming to remain competitive in this fast-paced market.

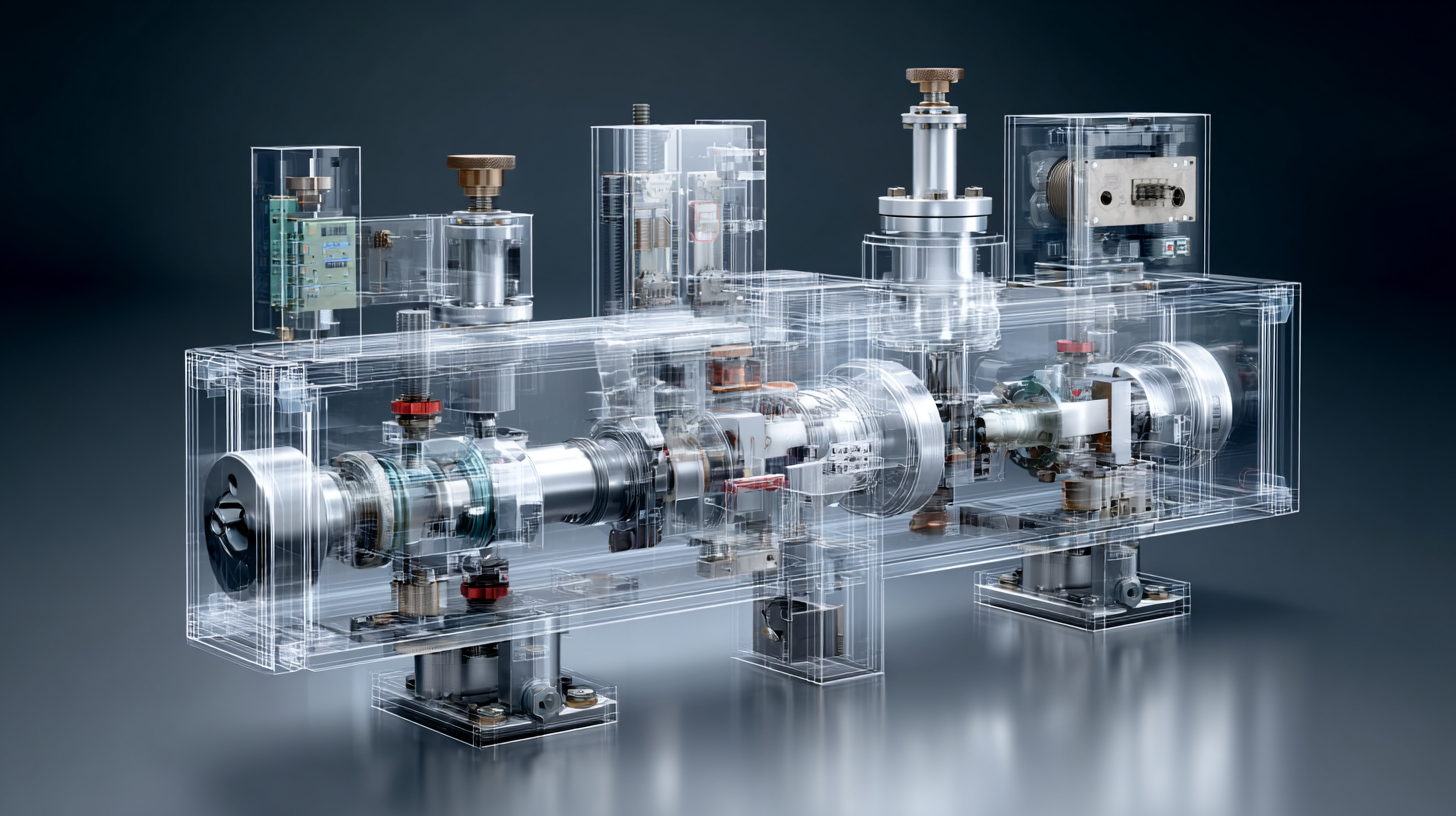

The role of valve vendors in industrial automation has become increasingly critical as industries strive for enhanced efficiency and productivity. The technological advancements introduced by these vendors have revolutionized the way processes are controlled and monitored. Modern valve technologies, such as smart actuators and positioners, allow for precise control of fluid dynamics, which is essential in maintaining optimal operational conditions. These innovations not only improve the responsiveness of control systems but also contribute to reduced energy consumption by ensuring that valves operate only when necessary.

Furthermore, valve vendor technologies integrate seamlessly with broader industrial automation frameworks, including SCADA and IoT systems. This interoperability enables real-time data collection and analysis, facilitating predictive maintenance and minimizing downtime. Vendors are also focusing on developing valves with enhanced durability and reliability, designed to withstand harsh industrial environments. As automation continues to evolve, the collaboration between valve vendors and manufacturers will be key to driving innovations that enhance operational efficiency and sustainability in various industries.

| Technology Type | Application Area | Key Benefits | Market Trends |

|---|---|---|---|

| Smart Valves | Oil & Gas | Improved monitoring and control | Increasing adoption of IoT |

| Electric Actuated Valves | Water Treatment | Energy efficiency and precision | Shift towards sustainability |

| Pneumatic Valves | Manufacturing | Quick response time | Growing emphasis on automation |

| Hydraulic Valves | Construction | High force generation | Development of smart industrial equipment |

| Control Valves | Chemical Processing | Enhances process control | Increase in digital solutions |

In the realm of modern industrial automation, valve vendors play a crucial role in enhancing system efficiency and reliability. Key players in this market, such as Emerson, Honeywell, and Siemens, continue to push the envelope with their innovative solutions. Emerson, for instance, has developed advanced smart valve technologies that integrate seamlessly with IoT platforms, enabling real-time monitoring and adaptive control. This innovation not only optimizes flow management but also reduces energy consumption in industrial processes.

Another significant player, Honeywell, has introduced cutting-edge pneumatic and electric actuators that offer high precision and responsiveness. Their focus on digital transformation emphasizes predictive maintenance, allowing industries to minimize downtime and improve overall operational performance. Siemens, on the other hand, is enhancing the valve market with their digital twin technology, which simulates valve performance under various conditions to enable better decision-making and proactive management. These advancements not only highlight the competitive edge of these valve vendors but also illustrate their vital contributions to advancing automation in the industrial sector.

Valves play a critical role in modern industrial automation, significantly enhancing process efficiency across various sectors. According to a report by the International Society of Automation (ISA), nearly 80% of industrial processes involve fluids, making valves essential for controlling flow rates, pressure, and temperature. By implementing advanced valve technologies such as smart valves and automated control systems, industries can achieve greater precision and reduce energy consumption.

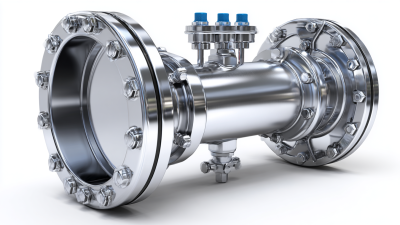

For instance, smart valves equipped with sensors can provide real-time data on performance, allowing for timely adjustments that optimize operational efficiency.

Furthermore, the global valve market is projected to reach $85 billion by 2027, driven by increasing demands for reliable and efficient fluid control solutions. The report highlights that industries embracing automation and smart manufacturing are witnessing efficiency improvements of up to 30% through the integration of modern valve technologies. This increase not only reduces operational costs but also minimizes downtime, ultimately leading to enhanced productivity. As the industrial landscape continues to evolve, the strategic role of valves in process efficiency will become increasingly paramount.

In the realm of modern industrial automation, valve vendors play a crucial role, yet they face significant challenges that can impede their efficiency and effectiveness. According to a report by the International Society of Automation, nearly 30% of valve vendors cite integration with advanced technologies, such as IoT and AI, as a primary hurdle. The rapid pace of technological change demands that vendors not only upgrade their product lines but also ensure compatibility with existing systems, a task that can be both costly and complex.

Another substantial challenge is the increasing demand for sustainability and energy efficiency. A recent study by the American Society of Mechanical Engineers highlights that about 40% of industrial valve usage can be optimized for energy savings. This places additional pressure on vendors to innovate and provide eco-friendly solutions while managing costs. To navigate these pressures, vendors must invest in research and development to stay ahead of sustainability trends.

**Tip:** Valve vendors should consider forming strategic partnerships with technology firms to enhance their product offerings and streamline integration processes.

Furthermore, supply chain disruptions have become prevalent in the wake of global events, affecting the availability of raw materials needed for valve manufacturing. The Manufacturing Purchasing Managers’ Index (PMI) indicates that supply chain constraints affected over 50% of companies in the sector last year. Addressing these challenges requires agility and resilience in operations to mitigate risks and maintain product delivery timelines.

**Tip:** Improving supply chain transparency through advanced analytics can help vendors anticipate disruptions and adapt more quickly.

This chart illustrates the perceived impact of various factors from valve vendors on industrial automation efficiency based on survey data.

The future of valve technology is poised to significantly influence industrial applications, driven by advancements in automation and efficiency. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 93.36 billion by 2025, growing at a CAGR of 5.6%. This growth is largely attributed to the increasing demand for automation in industries such as oil and gas, water and wastewater, and chemical processing. Enhanced valve technologies such as smart valves integrated with IoT capabilities are becoming vital for real-time monitoring and control, thereby streamlining processes and reducing operational costs.

In addition to traditional materials like stainless steel and cast iron, emerging composite materials are being incorporated into valve designs to enhance durability and reduce weight. A report from Research and Markets highlights that smart valves can lead to energy savings of up to 20% in some industrial applications by optimizing flow and pressure. Moreover, the rise of predictive maintenance, facilitated by sophisticated sensors, allows companies to foresee failures and minimize downtime, further increasing productivity. As industries continue to embrace these technological trends, the role of valve vendors will be crucial in shaping a more efficient and automated future in industrial settings.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.