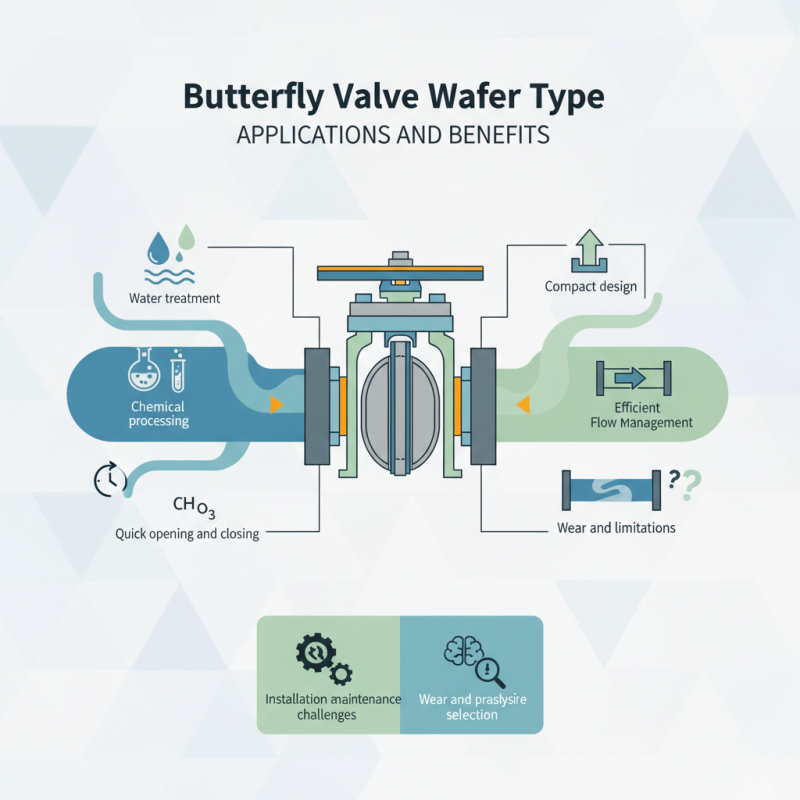

In the world of fluid control, the "butterfly valve wafer type" plays a crucial role. This specific type of valve is known for its compact design and efficient operation. Industry expert John Smith, a renowned engineer, once stated, "The wafer design optimizes space while ensuring effective flow management."

With its unique construction, the butterfly valve wafer type is widely used in various applications, including water treatment and chemical processing. It allows for quick opening and closing, making it ideal for systems that need rapid changes in flow. However, some users overlook potential issues, such as wear and pressure limitations in high-demand situations.

Despite its advantages, there can be challenges in installation and maintenance. It's essential to consider the specific requirements of each project. For many, understanding the complexities of choosing the right valve can be daunting. Always remember: while the butterfly valve wafer type offers benefits, every selection demands careful analysis.

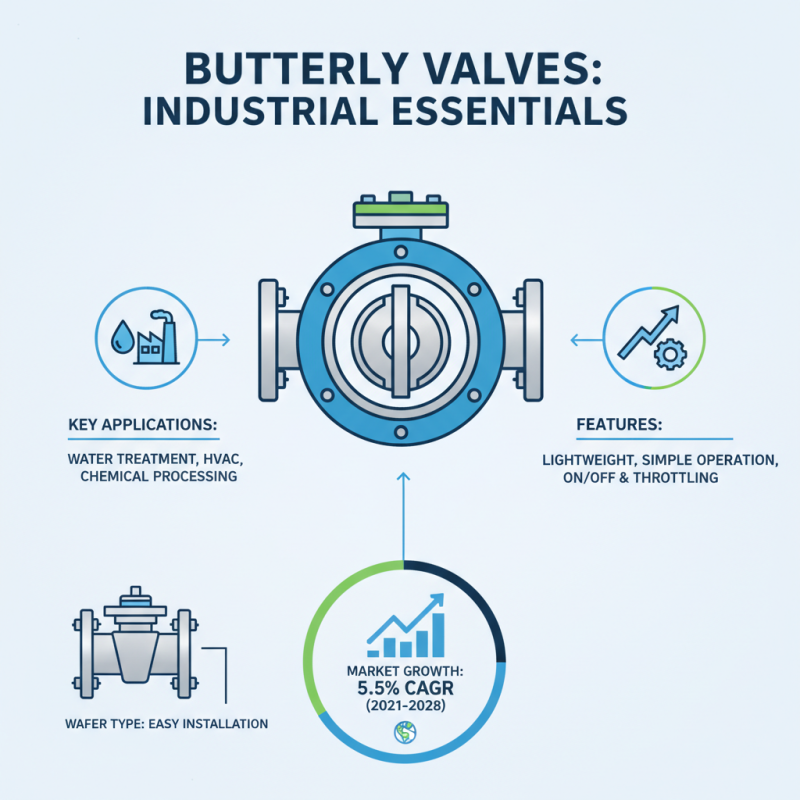

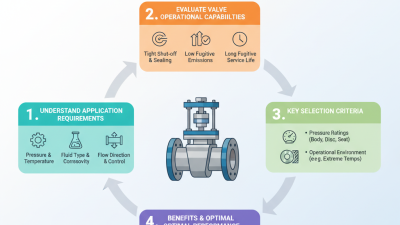

Butterfly valves are essential in various industrial applications due to their lightweight design and simple operation. Used primarily for on/off and throttling services, they have gained importance in sectors like water treatment, HVAC, and chemical processing. The wafer type, a popular variant, fits between flanges, making installation straightforward. Industry reports indicate that the global butterfly valve market is projected to grow at a CAGR of 5.5% from 2021 to 2028.

There are different types of butterfly valves, including resilient seated and metal seated versions. Each type serves distinct functions based on the application. Resilient seated valves provide tight sealing in low-pressure scenarios. Metal seated options are suitable for high-temperature applications. A recent study found that resilient seated butterfly valves are preferred in 80% of water treatment projects due to their reliability.

Despite their advantages, challenges persist. Users often struggle with maintenance issues over time. Improper installation can lead to leaks and environmental concerns. Manufacturers acknowledge these issues, but improvements take time. Recognizing these imperfections is critical for future advancements in valve technology.

Wafer type butterfly valves offer unique features that make them versatile in various applications. These valves are characterized by their compact design. They are lightweight, making them easy to install. The disc of the valve remains in the flow stream, which enhances efficiency. According to industry reports, around 30% of valves used in water treatment facilities are of the wafer type. This illustrates their high adoption rate in critical systems.

Design-wise, wafer type butterfly valves are typically sandwiched between flanges. This configuration reduces the need for additional supports. Their low torque requirements allow for easier operation. However, their performance can be inconsistent if not properly maintained. Some installations report issues with sealing, leading to leaks. This is critical, especially in environments where precision is essential.

A study highlights that maintaining proper alignment during installation can significantly improve performance. Therefore, attention to detail during setup cannot be ignored. Evaluations of lifecycle costs show that while these valves are affordable, neglecting routine maintenance can lead to higher long-term expenses. Thus, operators must balance initial savings with ongoing upkeep.

Wafer type butterfly valves are increasingly popular in various industries. They offer significant advantages for fluid control and flow regulation. These valves are lightweight and compact. Their design allows for easy installation and maintenance, which is a plus for busy facilities. However, some users underestimate their importance. Choosing the wrong valve type can lead to issues, such as leaks or inefficiencies.

In the food and beverage industry, wafer type butterfly valves help maintain hygiene and safety. They regulate the flow of liquids with precision. The smooth seating surface minimizes residue buildup, crucial for cleanliness. But sometimes, operators overlook the need for regular inspections. In the chemical industry, these valves handle corrosive substances. Though effective, improper selection can damage the valve over time.

Power plants and water treatment facilities also benefit from these valves. They manage large volumes of water with ease. The efficiency of wafer type butterfly valves can reduce operation costs. However, if installation mismatches occur, the results can be problematic. Understanding each industry’s specific needs is essential for optimal performance. Regular training and awareness can enhance valve reliability and lifespan.

Wafer type butterfly valves have gained popularity in various industries due to their unique benefits in fluid control. These valves offer a lightweight design, making them easy to install and maintain. According to a recent market report, the demand for wafer type butterfly valves is expected to grow by 5% annually. This growth is driven by their efficiency in handling different fluid media.

These valves provide excellent flow regulation. Their simple movement mechanism allows for quick opening and closing. This capability minimizes downtime and enhances operational efficiency. Moreover, the compact design saves valuable installation space. In scenarios where every inch counts, these valves prove their worth.

Tip: When selecting a wafer type valve, consider the specific fluid characteristics. Different materials can affect performance in varying conditions.

Another advantage is their cost-effectiveness. The manufacturing process of wafer butterfly valves is generally more economical. This can lead to lower initial investment costs. However, some users report challenges with sealing performance. Regular maintenance is essential to avoid leaks over time.

Tip: Always follow manufacturer guidelines for proper maintenance to extend the valve’s lifespan.

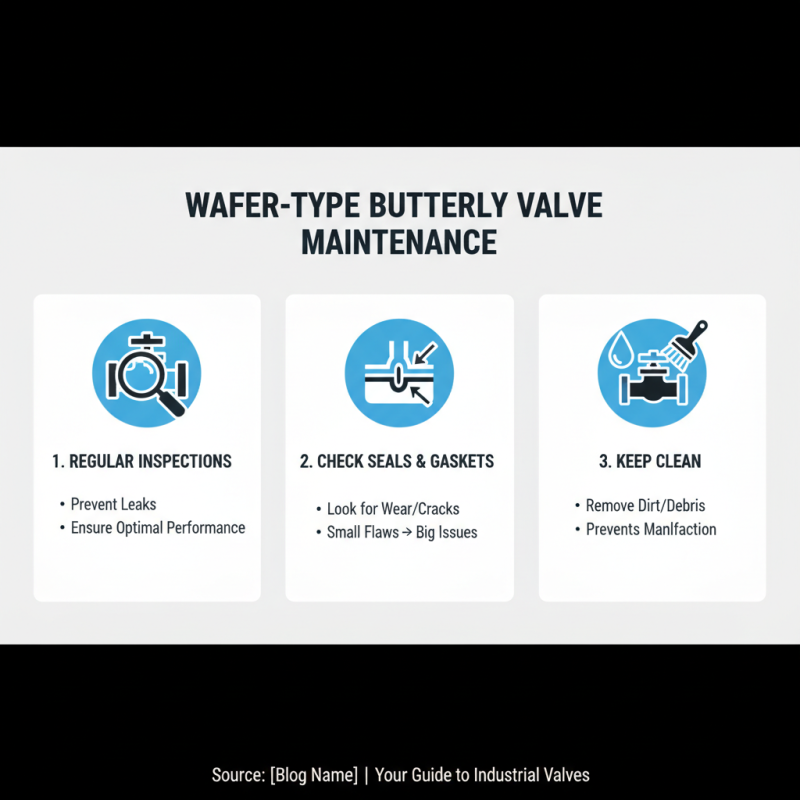

When it comes to wafer type butterfly valves, proper maintenance is crucial. Regular inspections can prevent leaks and ensure optimal performance. Check the seals and gaskets for signs of wear. A small crack can lead to significant issues. It's essential to keep the valve clean. Dirt and debris can cause malfunction over time.

Installation is equally important. A misalignment can disrupt flow and cause unnecessary stress on the valve. Make sure the butterfly valve sits flat against the flanges. Use appropriate torque when fastening bolts. Over-tightening can damage the valve. It's helpful to consult installation guides, but sometimes they may not cover all scenarios.

Remember that experience matters. Mistakes are part of the learning process. Sometimes, you may skip a step or overlook a detail during installation. Note these moments. Reflecting on them can help improve your technique. With time, you'll develop a better intuition for what works and what doesn’t.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.