The flanged butterfly valve is a crucial component in various industrial applications, known for its reliability and efficiency in controlling the flow of fluids. According to industry expert Dr. Emily Carter, a leading authority in valve technologies, "A flanged butterfly valve is not just a simple device; it's an essential tool that can optimize system performance and reduce maintenance costs." This statement underscores the importance of understanding how a flanged butterfly valve works and its various applications.

These valves utilize a rotating disc to regulate flow, making them ideal for applications requiring quick shut-off and precise flow control. The design allows for a compact installation, which is particularly advantageous in spaces with size constraints. Additionally, the flanged connection ensures a robust seal between the valve and the piping, enhancing the overall integrity of the system.

As industries continue to advance, the need for efficient fluid handling equipment like the flanged butterfly valve becomes increasingly critical. By delving into its workings, benefits, and applications, professionals in the field can leverage this knowledge to enhance operational efficiency and reliability in their respective systems.

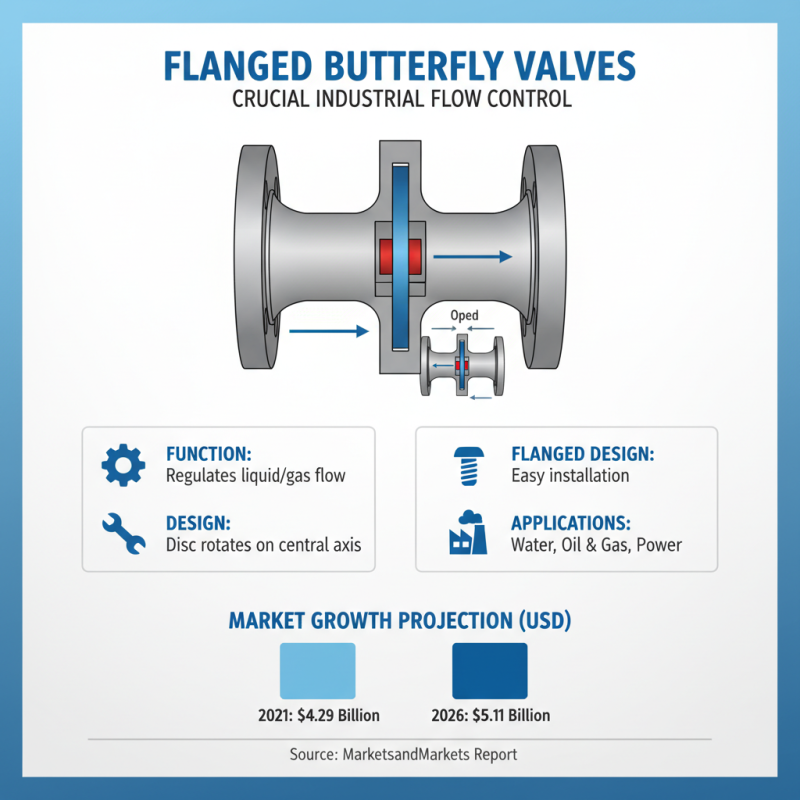

A flanged butterfly valve is a crucial component in various industrial applications, serving as a flow control mechanism within piping systems. Characterized by its disc-shaped closure element that rotates around a central axis, it effectively regulates the flow of liquids and gases. The flanged design enhances its installation flexibility, allowing for easy connections to different piping systems. According to a report by MarketsandMarkets, the butterfly valve market is projected to grow from USD 4.29 billion in 2021 to USD 5.11 billion by 2026, indicating rising demand across industries such as water and wastewater, oil and gas, and power generation, where flanged butterfly valves are often utilized.

In terms of design features, flanged butterfly valves typically possess a simpler structure compared to other valve types, which contributes to their lightweight and compact nature. The body is usually constructed from durable materials like cast iron, stainless steel, or plastic, ensuring resistance to corrosion and extending service life. Notably, the design allows for quicker opening and closing times, with the ability to achieve full flow in just a quarter turn. A comprehensive study by Research and Markets revealed that the increasing requirement for efficient fluid control in industrial processes is a key driver for the adoption of flanged butterfly valves, reflecting their importance in modern engineering solutions.

Flanged butterfly valves are widely used in various industries for their efficient design and functionality. The working principle of these valves is quite straightforward. At its core, a flanged butterfly valve consists of a circular disc or plate, which is positioned in the center of the pipe. This disc is connected to a shaft that allows it to rotate. When the valve is closed, the disc is perpendicular to the flow of fluid, effectively blocking it. Conversely, when the valve is opened, the disc rotates parallel to the flow, allowing fluid to pass freely.

The operation of flanged butterfly valves is based on the simple mechanism of rotation. When the operator turns the handle or actuator connected to the valve shaft, the disc pivots to either open or close the valve. This rotation typically occurs through 90 degrees. The design ensures that minimal space is required for the valve operation, which is ideal for both horizontal and vertical installations. Additionally, flanged connections provide a secure and leak-proof seal between the valve and the pipe, enhancing the overall reliability of the system. The straightforward design and ease of operation make flanged butterfly valves a popular choice in applications ranging from water supply to chemical processing.

Flanged butterfly valves are increasingly recognized for their efficiency and effectiveness in a variety of industrial applications. One of the primary advantages of these valves is their ability to provide excellent flow control, which is essential in managing large volumes of fluids. According to a 2022 report by the Global Valve Market Analysis, flanged butterfly valves constitute approximately 25% of the valve market, owing to their low pressure drop characteristics. This makes them particularly beneficial for systems requiring rapid flow modulation while minimizing energy consumption.

Additionally, flanged butterfly valves are celebrated for their durability and ease of installation. Their robust design allows them to withstand high-pressure conditions, making them suitable for industries such as oil and gas, water treatment, and chemical manufacturing. A recent study by Industrial Valve Report indicated that the projected demand for flanged butterfly valves is expected to grow by 6.5% annually through 2030, largely due to their reliability and the increasing need for effective fluid management in industrial processes. This combination of advantages not only enhances operational efficiency but also contributes to cost savings in maintenance and replacement over the valve's lifespan.

| Feature | Details |

|---|---|

| Definition | A flanged butterfly valve is a type of valve that uses a rotating disc to regulate fluid flow. |

| Material | Typically made from materials such as stainless steel, cast iron, or PVC for durability. |

| Applications | Used in water supply, wastewater management, chemical processing, and HVAC systems. |

| Operating Principle | Flow is controlled by the rotation of the disc, which can be opened or closed with a quarter-turn. |

| Size Range | Available in various sizes, typically from 2 inches to 48 inches in diameter. |

| Advantages | Lightweight, low pressure drop, quick operation, and minimal maintenance required. |

| Limitations | Not suitable for throttling services and may not provide a tight seal in off position. |

| Temperature Range | Can handle temperatures from -20°C to 120°C depending on the material. |

Flanged butterfly valves are crucial components in various industrial applications, characterized by their simple design and effective control of flow. The construction materials of these valves directly influence their performance, durability, and maintenance needs. Common materials used include stainless steel, ductile iron, and PVC, each offering distinct advantages suitable for specific environments and conditions. A report by Research and Markets highlighted that the demand for stainless steel flanged butterfly valves is expected to grow significantly, driven by their corrosion resistance and strength, which make them ideal for chemical processing and wastewater management.

Ductile iron is another prevalent choice due to its excellent mechanical properties and cost-effectiveness. It combines the strength of cast iron with greater ductility, allowing the valve to withstand high pressures and resist impact damage, making it a reliable option for power generation and water treatment facilities. According to a report from Grand View Research, the ductile iron valve market is set to increase as industries seek solutions that balance performance with budget constraints. PVC butterfly valves, while less durable than metal alternatives, offer outstanding resistance to chemicals and are lightweight, making them a preferred choice in agricultural and irrigation systems where ease of installation is crucial. Each material brings specific benefits that cater to the diverse needs of modern piping systems.

This chart displays the common materials used in flanged butterfly valves along with their benefits. Each material is represented by a bar illustrating its typical usage percentage in the industry.

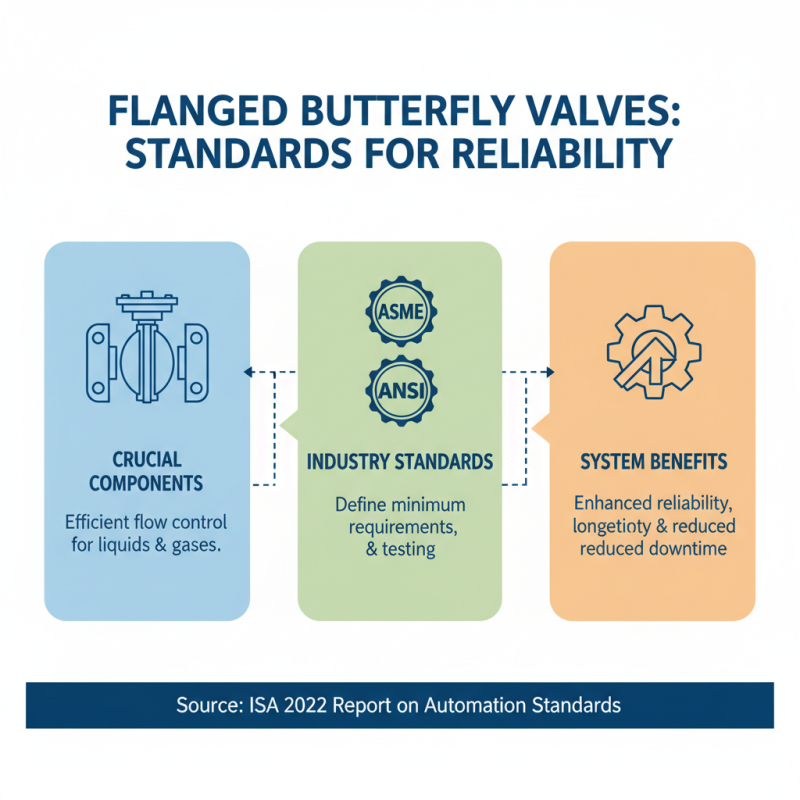

Flanged butterfly valves are crucial components in modern piping systems, providing efficient flow control for various liquids and gases. The industry standards and specifications governing these valves play a significant role in ensuring their functionality and safety. The American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) have established guidelines that define minimum performance requirements, materials, and testing procedures for flanged butterfly valves. According to a 2022 report by the International Society of Automation, compliance with these standards can enhance system reliability and longevity, significantly reducing unexpected downtimes.

In addition to ASME and ANSI, the European Committee for Standardization (CEN) has published EN 593, outlining specific criteria for butterfly valves used in industrial applications. This standard addresses design features, materials, and testing methods, ensuring valves can withstand pressure fluctuations and environmental stresses. A study by the Valve Manufacturers Association in 2021 indicated that adherence to such specifications not only fosters safety but also optimizes operational efficiency, which is critical in sectors like water treatment and oil and gas, where improper valve function can lead to significant economic losses and safety hazards.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.