Choosing the right y strainer valve is essential for effective fluid management. This valve plays a critical role in preventing debris from entering pipelines. With various options available, the selection process can seem daunting.

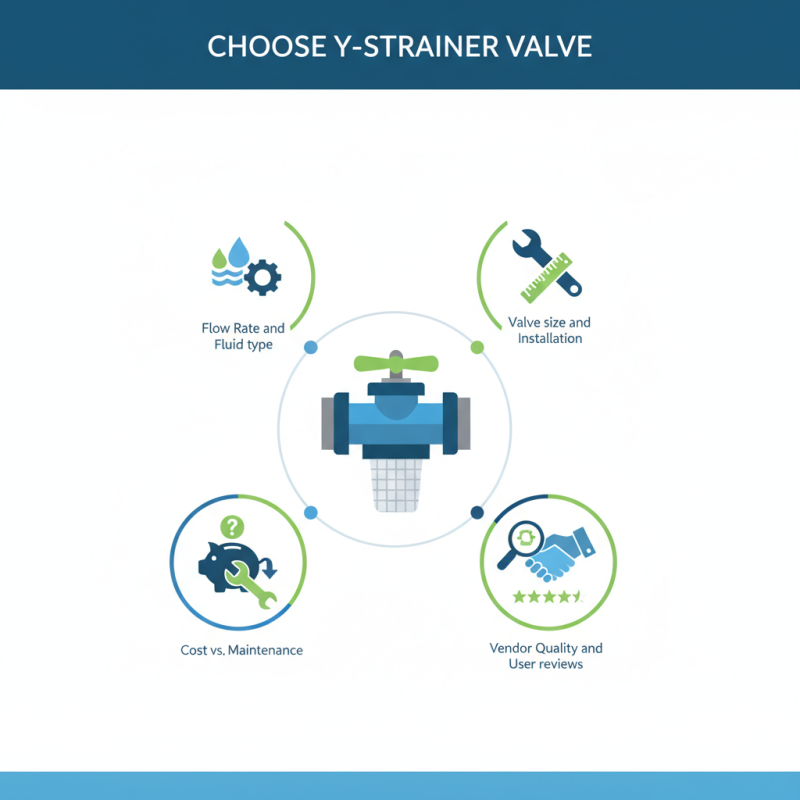

Consider factors like flow rate and the type of fluid. The size of the y strainer valve also matters. A common mistake is choosing based solely on cost. Sometimes, a cheaper valve may lead to higher maintenance costs later.

Think about installation and maintenance. Some valves require more space and effort to install properly. Additionally, remember that not all vendors offer the same quality. Researching user reviews can provide valuable insights while dealing with these decisions. Making the right choice requires careful thought and reflection.

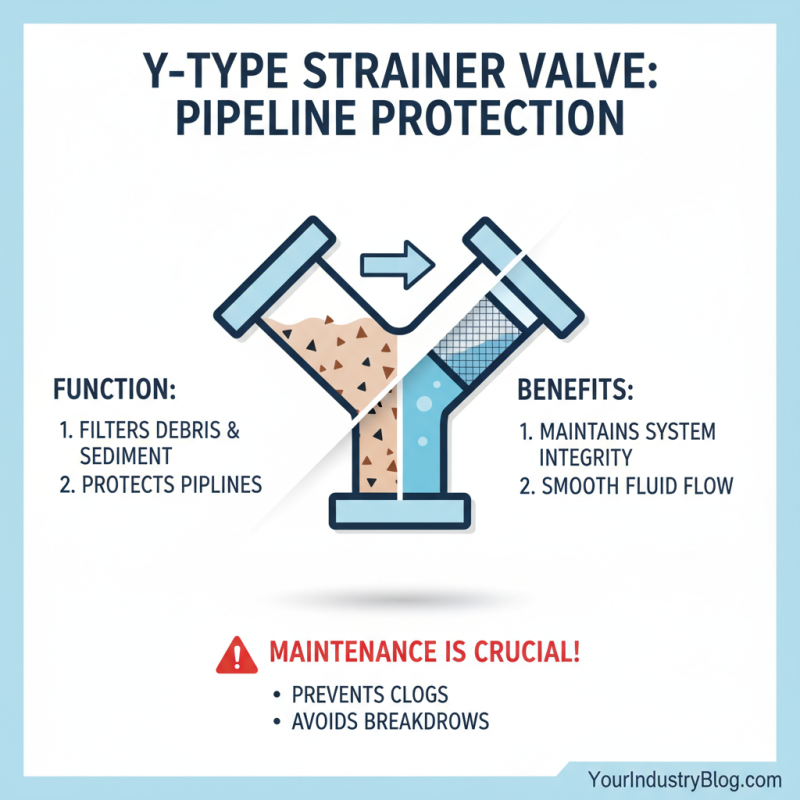

Y strainer valves play a crucial role in protecting pipelines from debris and sediment. They work by filtering out unwanted particles in liquids or gases. Their design features a "Y" shape, allowing fluid to flow smoothly while capturing impurities within a screen. This functionality helps maintain the integrity of the entire system. A clogged strainer, however, can create numerous issues. Regular maintenance is essential to avoid unexpected breakdowns.

When selecting a Y strainer valve, several factors should be considered. The fluid type is vital. Water, oil, or gas all have different characteristics. The mesh size of the strainer is an important detail. A finer mesh captures smaller particles but may clog quickly. Think about the flow rate as well. A high flow rate demands a strainer that won’t restrict movement significantly. The material of the valve matters too. Corrosion-resistant materials may be necessary in some settings.

Many users overlook the importance of installation. An incorrect setup can lead to inefficiencies. Ensure the strainer is accessible for cleaning. Neglect can turn a helpful device into a liability. Monitoring performance after installation is crucial. Is the strainer functioning as intended? Regular checks will enhance its lifespan and reliability. Understanding these functionalities can greatly assist in making informed decisions.

When selecting a Y strainer valve, understanding your specific application needs is crucial. Different industries require various specifications for optimal performance. The process industry, for instance, often demands strainers that can handle high pressures and extreme temperatures. According to a recent industry report, 70% of mechanical failures relate to improper strainer selection. This highlights the importance of identifying your needs before making a choice.

You should consider the type of fluid your system will handle. Is it viscous, corrosive, or abrasive? The right strainer material can prevent leaks and extend the lifecycle of your equipment. Data shows that stainless steel strainers tend to provide better durability, especially in harsh environments. Another factor is the flow rate. Selecting a strainer that can't accommodate your required flow can lead to costly downtime and increased maintenance.

Installation conditions are often overlooked. Limited space may restrict your choices. So, always measure the dimensions where you plan to install the strainer. It's advisable to consult with engineers or technicians who understand the nuances of your specific setup. Remember, asking questions and seeking professional advice can ultimately save you time and money in the long run.

| Application Type | Fluid Type | Mesh Size (Mesh) | Nominal Size (Inches) | Max Pressure (psi) | Temperature Range (°F) |

|---|---|---|---|---|---|

| Chemical Processing | Acids and Bases | 40 | 2 | 150 | 32 to 140 |

| Water Treatment | Potable Water | 100 | 3 | 200 | 40 to 150 |

| Food Processing | Food Grade Liquids | 60 | 4 | 150 | 35 to 180 |

| HVAC Systems | Heating Water | 80 | 2.5 | 250 | 30 to 200 |

| Oil and Gas | Hydrocarbons | 30 | 6 | 300 | -20 to 250 |

When selecting a Y strainer, material compatibility is crucial. Different fluids react differently with materials. You must consider the fluid type you will filter. For instance, corrosive substances require stronger materials to prevent degradation.

Stainless steel and bronze are popular options, but they have limitations. Stainless steel can handle high temperatures well, yet it may not work with harsh chemicals. Bronze offers good strength and corrosion resistance but can fail under extreme conditions.

It’s essential to go beyond standard materials. Think about the environment too. Will the strainer be exposed to extreme temperatures or pressures? Make sure to evaluate those conditions. Not every choice is perfect, and sometimes compromises are necessary. The right decision often comes from thorough research and weighing all factors carefully.

This chart illustrates the compatibility ratings of different materials used for Y strainer valves. A rating of 1 indicates poor compatibility, while a rating of 10 indicates excellent compatibility. This information can help you select the right Y strainer valve based on material compatibility for your specific needs.

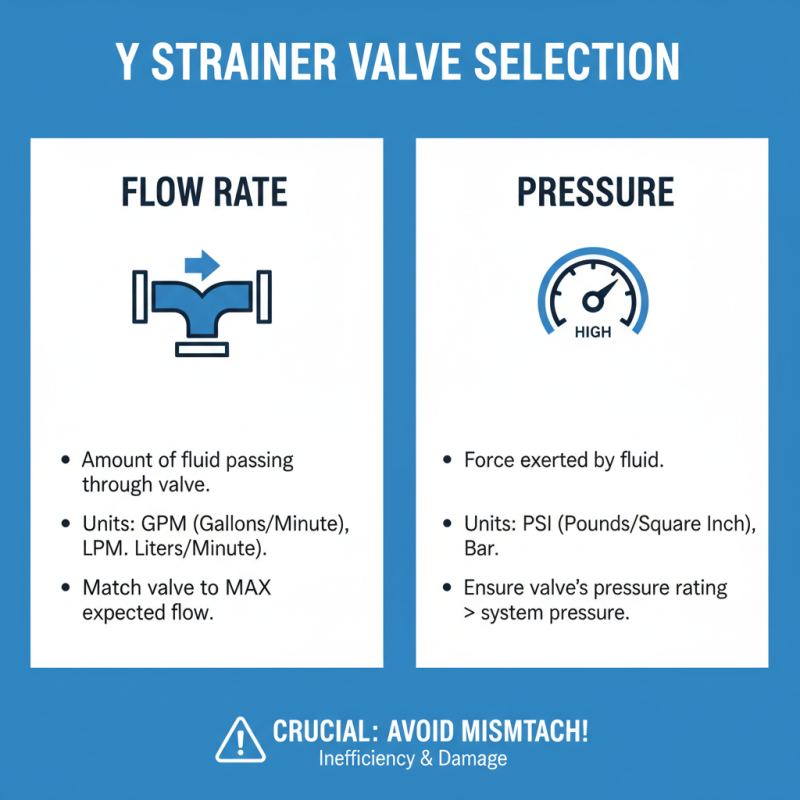

When selecting a Y strainer valve, understanding flow rate and pressure requirements is crucial. Flow rate indicates how much fluid can pass through the valve. Measure in gallons per minute (GPM) or liters per minute (LPM). Ensure that your valve can handle the maximum expected flow. A mismatch can lead to inefficiency or even damage.

Pressure is another vital factor. The valve should withstand the system's pressure without leaking. Check the pressure ratings and operational limits specified by the manufacturer. Poor performance can result from an inadequate choice. Sometimes, users ignore the pressure drop that occurs across a strainer. This can affect system performance, leading to unexpected downtime.

In addition, consider the medium flowing through the strainer. Is it clean water or abrasive fluid? The material of the strainer must align with the fluid type. An incorrect choice may lead to premature wear. Evaluate your entire system before making a decision. It’s essential to reflect on all these details for a successful choice.

When selecting a Y strainer valve, maintenance and installation are key factors. Proper installation will enhance performance and longevity. Ensure that the strainer is correctly positioned in the pipeline. This positioning impacts the flow rate and efficiency. Tighten the fittings, but be careful not to over-tighten. Check for leaks after installation.

Tips: Always inspect your Y strainer regularly. Accumulated debris can hinder flow. A small amount of dirt can create big issues. Clean the strainer according to the manufacturer's recommendations. This small maintenance task can prevent significant downtime and repairs.

Incorporating a drain valve can simplify cleaning. It allows for quick removal of captured particles. However, not every setup needs this feature. Evaluate your specific needs before opting for extra components. Occasionally, users find their strainers clogged sooner than expected. It’s essential to conduct frequent checks, especially in high-usage scenarios.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.