Choosing the right Y strainer valve for your plumbing needs is crucial for maintaining the efficiency and longevity of piping systems. With the insights from renowned industry expert John Smith, who states, "The correct selection of a Y strainer valve not only protects your equipment but also optimizes fluid flow," it becomes evident that understanding the key features and specifications of these valves is essential.

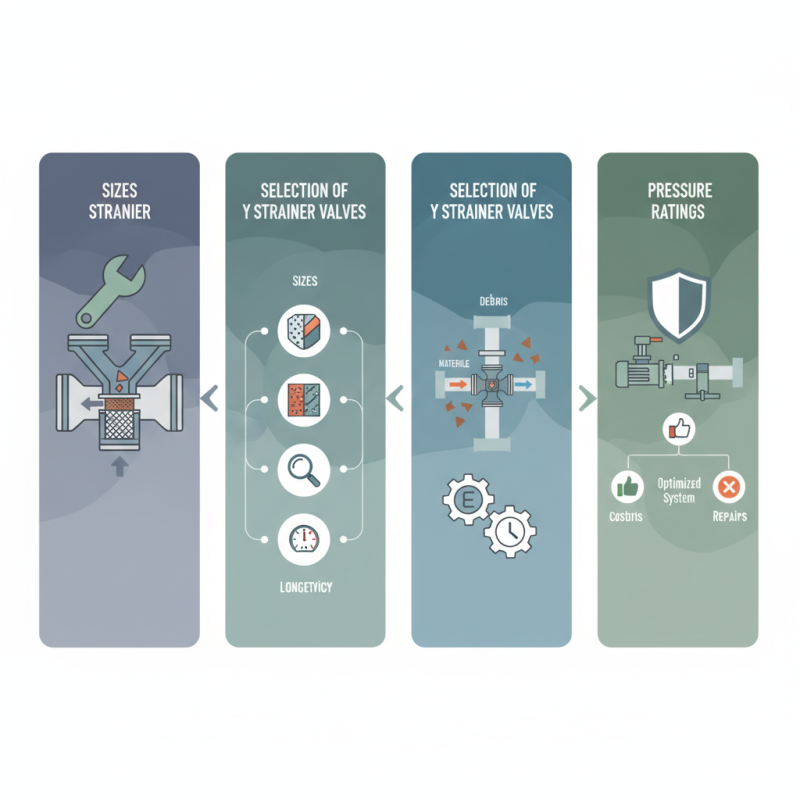

In the plumbing industry, Y strainer valves play a pivotal role in preventing debris and contaminants from entering pipelines, which can lead to costly repairs and downtime. As such, knowing what to look for when selecting a Y strainer valve can significantly impact the performance of your entire water system. From sizes and materials to filtration levels and pressure ratings, the decision-making process can be complex, but it is fundamental for any successful plumbing project.

Therefore, by diving deep into the considerations that surround Y strainer valve choices, we aim to equip professionals and DIY enthusiasts alike with the knowledge necessary to make informed decisions that will elevate the integrity and efficiency of their plumbing systems.

Y strainer valves are essential components in many plumbing systems, serving as a vital line of defense against unwanted debris and contaminants. Their primary function is to filter out particles from liquids that flow through piping systems, thereby preventing clogging and damage to more sensitive equipment, such as pumps and valves. This is particularly important in industrial applications, where even small amounts of debris can lead to significant operational issues. By ensuring a clear flow, Y strainers help maintain the efficiency and longevity of the plumbing system.

The importance of Y strainer valves extends beyond mere filtration; they contribute to the overall safety and reliability of plumbing systems. When installed correctly, they help prevent costly repairs and downtime that can result from blockages or failures caused by foreign particles. Understanding the specifications and flow rates applicable to specific applications is crucial when selecting a Y strainer valve. Factors such as the type of fluid, temperature, and pressure should inform the choice of strainer size and mesh rating, ensuring optimal performance and protection of the plumbing infrastructure.

When selecting a Y strainer valve for your plumbing needs, understanding the key features is crucial for optimal performance and longevity. One primary consideration is the material of the strainer. Y strainers are typically available in materials such as stainless steel, cast iron, and plastic. According to industry reports, stainless steel is often preferred for its corrosion resistance and durability in high-pressure applications, whereas plastic options are suitable for low-pressure systems where chemical resistance is essential. The choice of material can significantly impact the strainer's lifespan and maintenance requirements.

Another important feature to consider is the mesh size of the strainer. The mesh size will determine the type and size of particles that can be filtered out. For instance, a mesh size of 100 mesh (149 microns) may be adequate for general applications, but in high-purity environments, finer meshes might be required. Industry standards suggest that selecting the appropriate mesh size based on the specific contamination level in your system can lead to improved efficiency and reduced maintenance costs. Additionally, the flow rate capacity of the Y strainer should align with your system's requirements, as undersized strainers can cause flow restrictions and potential system failures. Regular assessments of these features can ensure that the chosen Y strainer valve meets your plumbing needs effectively.

When selecting the right Y strainer valve for your plumbing needs, it's crucial to understand the various types available and their specific applications. Y strainers are essential for protecting pipelines by filtering out debris and contaminants from liquids and gases. According to industry reports, approximately 60% of plumbing failures can be attributed to the presence of particulate matter; therefore, choosing the right strainer type is vital for system longevity and efficiency.

There are several different types of Y strainers, including cast iron, stainless steel, and plastic models. Cast iron Y strainers are often used in water and wastewater applications due to their durability and resistance to corrosion. Stainless steel strainers, on the other hand, are favored in food processing and pharmaceutical industries for their cleanliness and resistance to high temperatures. Plastic Y strainers can be beneficial in less demanding environments, as they are lightweight and resistant to certain corrosive chemicals, making them suitable for specific chemical processing roles. According to a recent market analysis, the demand for stainless steel Y strainers has grown by 20% annually in sectors where hygiene is paramount, reflecting the industry's shift towards safer material solutions.

Selecting the appropriate Y strainer not only involves considering the material and application but also factors such as flow rate and pressure drop. According to engineering guidelines, a pressure drop of more than 5 psi across the strainer can indicate the need for cleaning or replacement. This data suggests that regular maintenance and timely upgrades of strainer valves are key to ensuring optimal performance, minimizing downtime, and prolonging the life of plumbing systems.

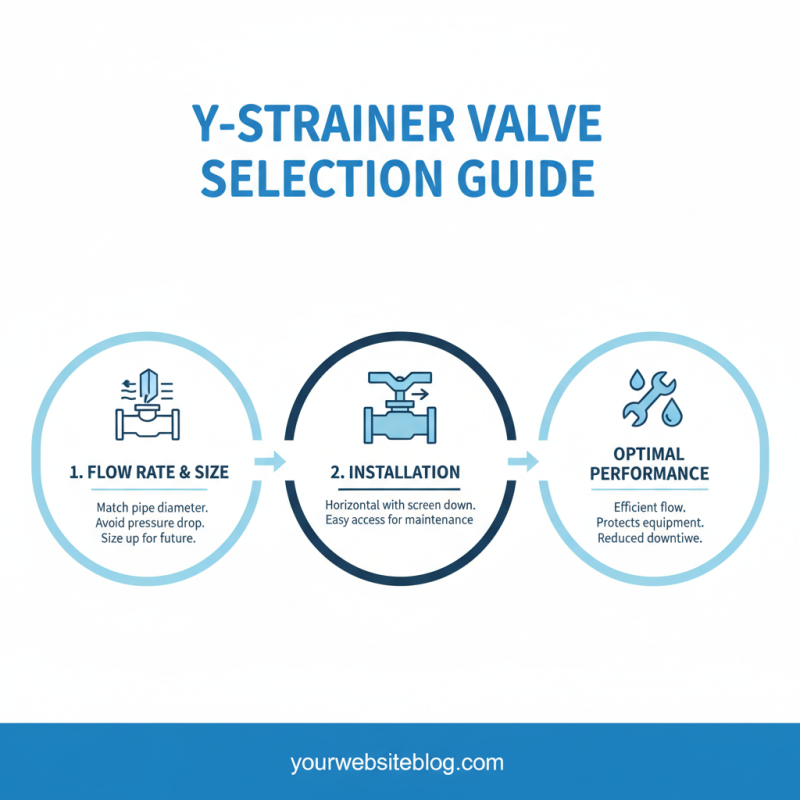

When selecting a Y strainer valve for your plumbing needs, sizing and installation are crucial to ensure optimal performance. First, consider the flow rate of your system. The appropriate size of the Y strainer should match the pipe diameter and meet the required flow rate without causing excessive pressure drop. Typically, it is advisable to choose a strainer that has a diameter at least equal to the pipe size to maintain efficient flow. Also, anticipate any potential future upgrades to your plumbing system by sizing the strainer slightly larger if necessary.

Installation of the Y strainer valve should follow specific guidelines to maximize its effectiveness and longevity. It is essential to install the strainer in a location where it can be easily accessed for maintenance and cleaning. Ensure that the inlet and outlet of the strainer are properly aligned with the flow direction, which is often indicated by an arrow on the valve body. Additionally, consider installing the strainer in a horizontal position to promote optimal debris collection in the straining element. Regular maintenance, including routine inspection and cleaning of the strainer mesh, is vital to prevent blockages and maintain system efficiency.

When selecting the right Y strainer valve for plumbing systems, maintenance is critical to ensure optimal performance and longevity. Regular inspections can significantly reduce the risk of malfunctions caused by debris and sediment buildup. According to a study by the American Society of Plumbing Engineers (ASPE), about 30% of plumbing failures are attributed to inadequate strainer maintenance. Periodic cleaning and replacing of the strainer elements can prevent substantial issues, reducing system downtime and repair costs.

Tip 1: Schedule routine maintenance every six months to inspect your Y strainer valve. During inspection, check for signs of wear, corrosion, or blockages. This proactive approach can extend the life of your valve and maintain system efficiency.

Additionally, maintaining the proper pressure conditions is essential for Y strainers to function effectively. A drop in pressure can indicate a blockage or failure, while excessive pressure can lead to premature wear. According to the Hydraulic Institute, maintaining optimal flow rates can improve system efficiency by up to 15%.

Tip 2: Use pressure gauges to monitor operating conditions regularly, ensuring they remain within the manufacturer’s recommended limits. Keeping track of these metrics can help you identify potential issues before they affect performance. By adhering to these maintenance tips, you can ensure that your Y strainer valve consistently operates at peak efficiency.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.