Choosing the right valves for your plumbing needs is essential to ensure efficiency, safety, and longevity in any plumbing system. According to the recent market analysis by Research and Markets, the global valve market is projected to reach USD 120 billion by 2027, underscoring the importance of making informed choices when it comes to valve valves. With various types, materials, and applications available, navigating the landscape can be overwhelming for both professionals and DIY enthusiasts alike.

Industry expert John Smith, a noted authority in fluid dynamics, emphasizes the critical nature of this selection process, stating, "The right valve valves can significantly improve system performance and reduce maintenance costs in the long run." As plumbing systems continue to evolve, staying updated with the latest innovations and standards is vital. This guide aims to provide you with essential tips and insights to make educated decisions that align with your specific plumbing requirements and project goals. Whether you’re facing a simple repair or undertaking extensive renovations, understanding the nuances of valve selection will ensure optimal functionality and reliability in your plumbing endeavors.

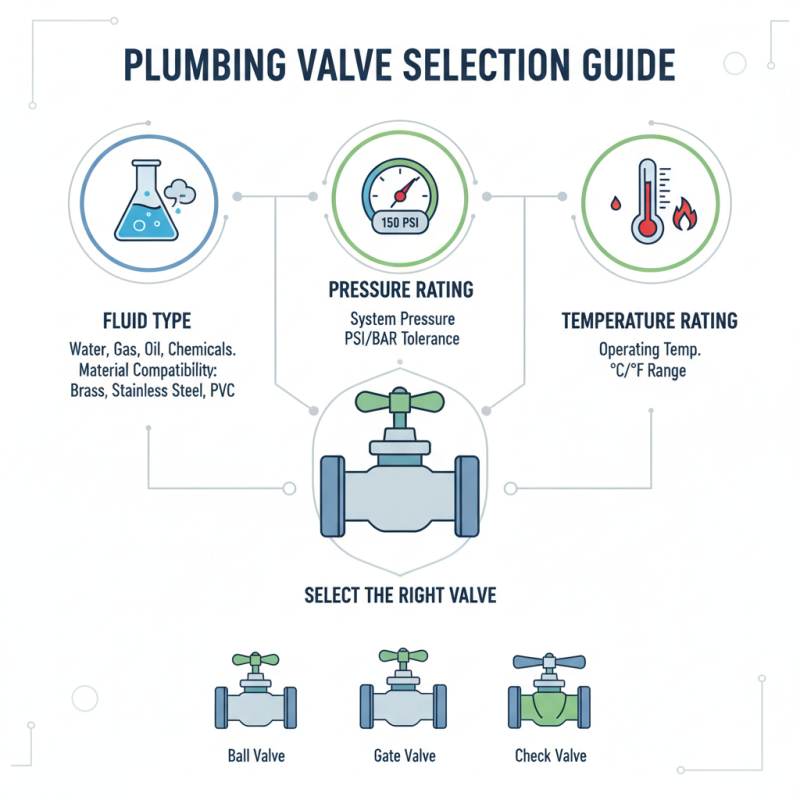

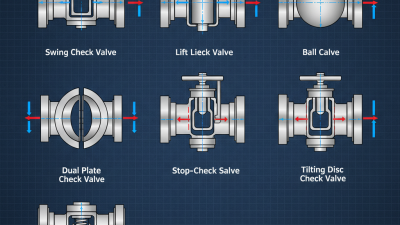

Valves are crucial components in plumbing systems, playing a vital role in regulating the flow of water and other fluids. Understanding the different types of valves available and their specific applications can significantly enhance the efficiency and safety of plumbing installations. According to a report by the Plumbing Manufacturers International (PMI), approximately 75% of plumbing issues can be traced back to improper valve selection and maintenance. It is essential to familiarize oneself with the most common types of valves—gate, globe, ball, and check valves—as each serves a distinct function.

For instance, gate valves are ideal for fully opening or closing a flow, making them suitable for applications where minimal pressure drop is desired, while globe valves excel in throttling flow control.

When selecting valves, factors such as pressure ratings, temperature limits, and the type of medium being used should be considered. For example, a study published in the Journal of Water Resources indicated that using the appropriate valve type could reduce system failures by up to 40% and extend the overall lifespan of plumbing systems. Additionally, the material of the valve is critical; brass valves, for example, are known for their durability and resistance to corrosion, making them a popular choice for both residential and commercial plumbing. Understanding these aspects not only aids in choosing the right valve but also ensures the reliability and longevity of the entire plumbing system.

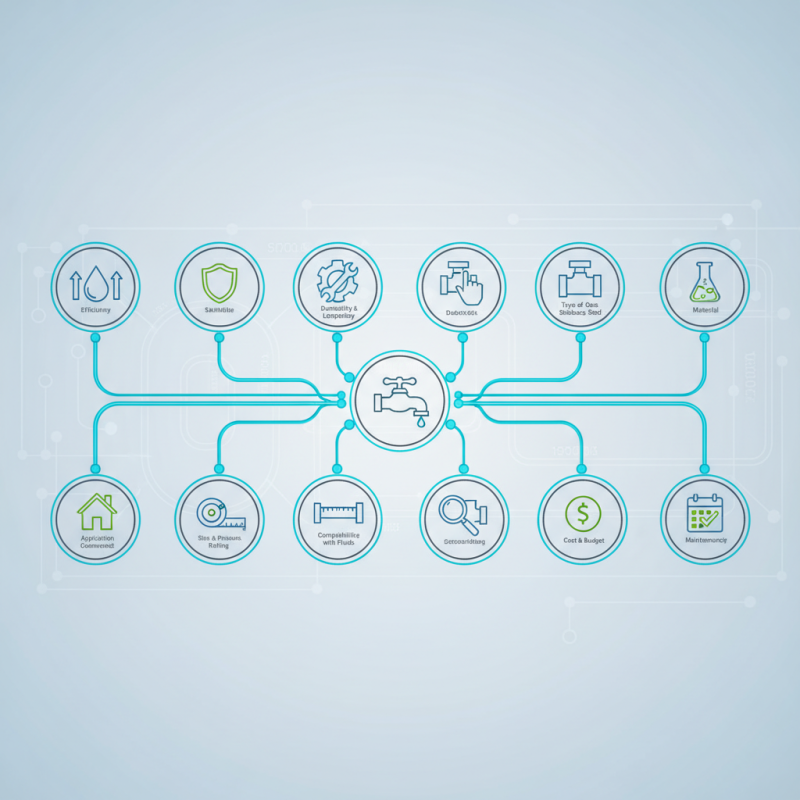

When selecting valves for your plumbing systems, several key factors should be at the forefront of your decision-making process. First, consider the type of fluid the valve will be handling. Valves have different materials and constructions suited for various liquids or gases, so understanding the compatibility with your specific application is crucial. Additionally, think about the pressure and temperature ratings required for your system. Choosing a valve that can withstand the expected conditions will ensure durability and performance.

Another critical aspect is the valve’s size and connection type. Implementing the right size will influence the flow rate and efficiency of your plumbing system. Moreover, ensure that the valve’s connection matches your existing pipes to prevent any installation issues.

Tip: Always check for certifications and quality standards relevant to valves in plumbing to ensure reliable performance and safety. Additionally, consider the ease of installation and maintenance; some valve designs are more user-friendly, making future servicing simpler. By keeping these key factors in mind, you can make informed decisions that will lead to a more efficient and reliable plumbing system.

When selecting the right valves for your plumbing needs, assessing material compatibility is an essential factor that can significantly impact the longevity and performance of your system. For example, different plumbing environments—such as residential, commercial, or industrial—demand various materials based on factors like temperature, pressure, and exposure to corrosive elements. According to a report by the American Society of Plumbing Engineers, improper material selection can lead to valve failure within the first year of installation, resulting in costly repairs and service disruptions.

One crucial tip for ensuring material compatibility is to consider the medium that will flow through the valves. For instance, if your plumbing system involves hot water, brass or stainless steel valves are preferable due to their resistance to heat and corrosion. Additionally, when dealing with aggressive fluids or chemicals, materials such as PVC or CPVC can offer better resilience and durability. Conducting a thorough analysis of the chemical properties and compatibility of the materials involved is vital for optimal valve performance.

Another important aspect is to evaluate the environment in which the valves will be installed. Factors such as humidity, exposure to sunlight, and the presence of salts or chemicals can all influence material degradation over time. Polypropylene valves, for example, can be an excellent choice for environments with high humidity and chemical exposure, as they provide superior resistance to corrosion and deterioration. By carefully assessing these factors and choosing materials that align with your specific plumbing environment, you can enhance the reliability and efficiency of your plumbing system while minimizing repair costs in the long run.

When selecting valves for plumbing applications, understanding valve size and pressure ratings is crucial for optimal performance. The valve size must correspond to the pipe diameter to ensure efficient flow and prevent any pressure drops. Industry standards suggest that the valve diameter should ideally match the nominal size of the connecting pipelines. According to a report by the American Society of Mechanical Engineers (ASME), improper sizing can lead to a 20-50% decrease in system efficiency due to turbulence and back pressure issues.

Pressure ratings are equally important; they determine how much pressure the valve can withstand without failing. Valves are typically rated according to standards such as ANSI or API, which outline maximum allowable working pressures. When choosing valves, it's advisable to select those with a pressure rating that exceeds the system’s maximum operating pressure by at least 25%. This extra cushion can significantly enhance safety and longevity.

One effective tip is to carefully evaluate the specific needs of your plumbing system before purchasing. Understanding the fluid type, maximum pressure, and anticipated flow rates will guide you in selecting the right valve size and pressure rating. Additionally, consulting with industry benchmarks can provide insights into best practices, such as using ball valves for quick shut-off capabilities, which can improve the overall efficiency of your plumbing system.

When selecting valves for plumbing applications, the importance of reliability and maintenance cannot be overstated. Valves are critical components that regulate flow and pressure in plumbing systems, and their failure can lead to significant disruptions and costly repairs. According to a report by the American Society of Civil Engineers, approximately 25% of water supply systems face issues related to valve integrity, highlighting the need for careful selection based on reliability metrics. Choosing high-quality, durable valves can mitigate the risk of leaks and inefficiencies, ensuring a consistent performance over time.

Maintenance is another crucial aspect of valve selection. A study published in the Journal of Water Management indicates that regular inspection and maintenance can extend a valve's lifespan by up to 40%. Selecting valves that are easier to maintain, with straightforward access points and replaceable components, can significantly reduce operational downtime and maintenance costs. Additionally, understanding the operating environment—such as temperature fluctuations and exposure to corrosive substances—is vital in picking the right type of valve. This attention to detail can greatly influence the overall longevity of the plumbing system, making reliability and maintenance central to the valve selection process.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.