Choosing the right gas safety valve is a crucial consideration for both homeowners and business owners, ensuring safe and efficient gas usage. According to industry expert Dr. Emily Foster, a renowned engineer in gas safety systems, “A properly selected gas safety valve can be the difference between a safe environment and a potentially hazardous situation.” With the increasing reliance on gas appliances and systems, understanding the critical factors that influence the selection of a gas safety valve is essential.

When it comes to protecting your premises from gas leaks and managing pressure, the right gas safety valve serves as a vital line of defense. Factors such as size, temperature rating, and pressure specifications are pivotal in ensuring that the valve operates effectively under your specific conditions. Furthermore, installation and maintenance play a significant role in the valve's performance over time.

In this guide, we will explore essential considerations when selecting a gas safety valve, shedding light on both technical aspects and best practices. By doing so, we aim to empower you with the knowledge needed to make informed decisions that enhance safety in your home or business.

Gas safety valves play a crucial role in protecting homes and businesses from the potentially dangerous consequences of gas leaks. These valves function by automatically shutting off the gas supply in case of a malfunction or irregularity in the system. According to the National Fire Protection Association (NFPA), gas leaks account for an estimated 20% of all home fires, underscoring the necessity for reliable safety devices. Understanding the importance and function of gas safety valves can ultimately save lives and reduce property damage.

When selecting a gas safety valve, it is essential to consider factors such as the valve's size, flow rate, and compatible materials. Moreover, the valve must meet the relevant industry regulations and standards to ensure optimal performance. A report from the American Society of Mechanical Engineers indicates that the proper installation and maintenance of gas safety valves can reduce gas leak incidents by up to 60%. It is advisable to consult with professionals when determining the appropriate specifications for your needs.

Tips: Regularly inspect your gas safety valves to make sure they are functioning correctly. Look for visible signs of wear or damage, and ensure that they are free from rust or debris. Additionally, consider scheduling routine maintenance checks with certified technicians to keep your gas supply system safe and operational. By being proactive, you can enhance the effectiveness of your gas safety measures considerably.

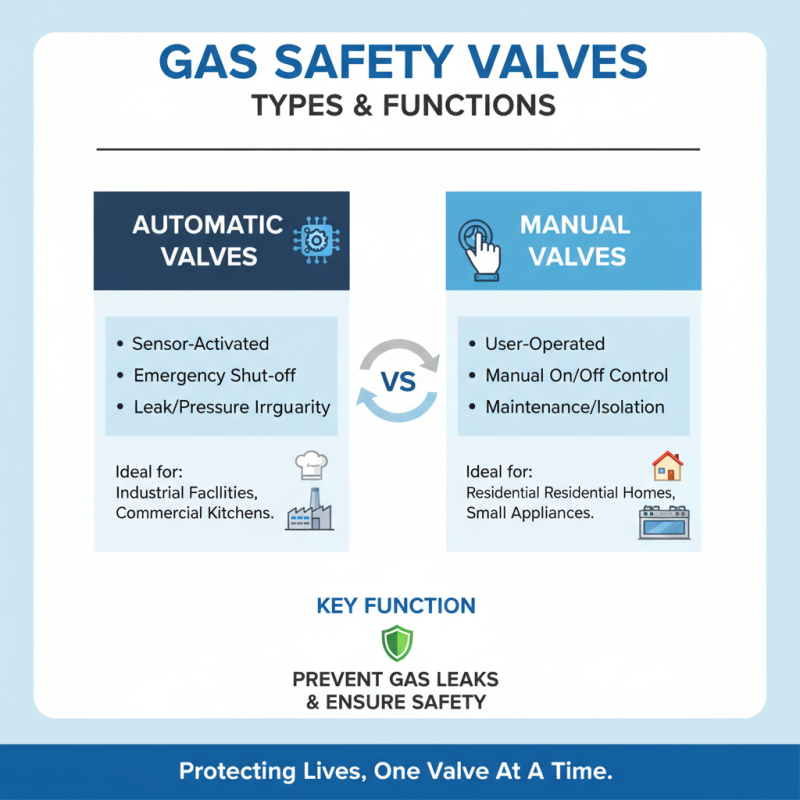

When it comes to ensuring safety in environments that utilize gas, understanding the various types of gas safety valves is crucial. There are primarily two categories of gas safety valves: automatic and manual. Automatic valves are designed to activate without user intervention, closing off gas flow in the event of a detected leak or pressure irregularity. These valves are often equipped with sensors that constantly monitor the system, making them essential for high-risk locations such as industrial facilities or large commercial kitchens.

On the other hand, manual gas safety valves require human operation to shut off the gas supply. These valves are typically used in residential settings where users can regularly monitor their gas appliances. Manual valves are commonly found in gas meters and are essential for maintenance or emergency situations. Each type serves an essential role in gas safety, and the selection between them will depend on the specific requirements of your home or business, considering factors such as usage frequency, potential hazards, and the level of automation desired. Understanding these options is vital for any property owner looking to prioritize safety in their gas systems.

When selecting a gas safety valve, there are several key factors to consider to ensure optimal safety and performance in both residential and commercial settings. One of the critical elements is the valve type, as various designs, including diaphragm, piston, and ball valves, offer different advantages. According to a report from the Global Gas Valve Market published by XYZ Research, diaphragm valves are noted for their reliable sealing capabilities, making them ideal for environments where gas leakage poses significant risks. Understanding your specific gas system requirements can assist in choosing a valve that enhances safety.

Another essential consideration is the pressure rating of the valve, which should align with the operational requirements of your facility. The American Gas Association highlights that selecting a valve with an appropriate pressure rating is crucial; a mismatched valve can lead to catastrophic failures. Additionally, it’s essential to evaluate the materials used in valve construction, ensuring they are compatible with the type of gas handled. For instance, some gases can cause corrosion in certain metals, underscoring the importance of using corrosion-resistant materials. The choice of a high-quality gas safety valve not only fulfills regulatory requirements but also promotes long-term reliability and safety in gas operations.

When selecting and installing a gas safety valve, proper maintenance is crucial to ensure the longevity and reliability of the device. According to a report by the National Fire Protection Association (NFPA), faulty gas systems are a leading cause of household fires, underscoring the importance of regular maintenance. It is recommended that homeowners and businesses schedule annual inspections to check for leaks, corrosion, and overall valve functionality. During these inspections, it is important to verify that the valve's seals are intact and that the unit operates smoothly under various pressures.

Tips for effectively maintaining gas safety valves include checking the valve’s manual for specific maintenance procedures. It is important to keep the area around the valve clean and free of any obstructions. Visual inspections should include assessing for signs of rust or wear and tear that could compromise the valve’s effectiveness. Additionally, consider keeping a maintenance log to track any issues or repairs. This practice can help in identifying patterns that may signal the need for a replacement or further inspection.

Another important aspect is the installation of the gas safety valve. Following the manufacturer's instructions meticulously during installation can significantly reduce the risk of operational issues. Ensure that the valve is placed in an accessible location for future inspections, and all connections should be tightened securely to prevent leaks. Overall, investing time and effort into proper installation and ongoing maintenance will enhance the safety and reliability of gas systems in any setting.

When selecting a gas safety valve for your home or business, it's crucial to consider the regulatory standards and compliance requirements that govern gas safety systems. These regulations are designed to ensure that gas appliances operate safely and efficiently, reducing the risk of leaks or other hazardous situations. Familiarizing yourself with local and national codes can help you make informed decisions and protect your property and occupants.

Tips: Always consult local building codes and industry regulations specific to gas safety systems in your area. This includes understanding standards set by organizations such as the National Fire Protection Association (NFPA) and the American National Standards Institute (ANSI). Ensuring compliance with these guidelines not only enhances safety but also prevents potential legal liabilities.

Moreover, regular inspections and maintenance of gas safety valves in accordance with regulatory standards are essential. Keeping up with these requirements can help identify potential issues before they escalate into serious problems.

Tips: Schedule periodic maintenance checks with certified professionals to ensure all gas components comply with current regulations. This proactive approach not only ensures safety but also extends the lifespan of your gas systems, ultimately providing peace of mind.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.