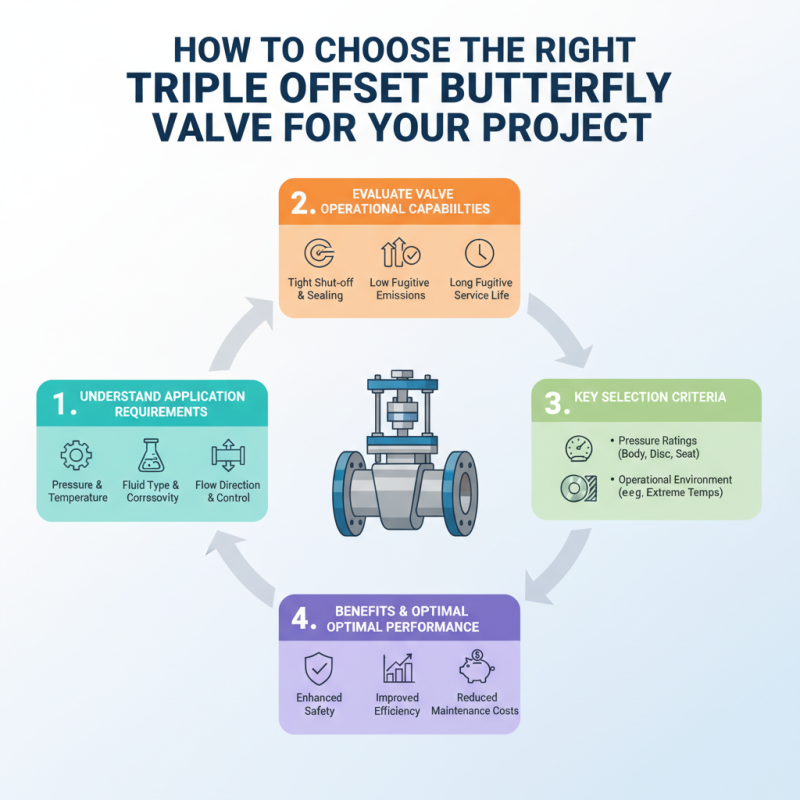

Choosing the right triple offset butterfly valve for your project is a critical decision that can significantly impact both the efficiency and safety of your operations. According to industry expert Dr. Emily Stone, a renowned valve specialist, "Selecting the correct triple offset butterfly valve hinges on understanding both the application requirements and the valve's operational capabilities." This underscores the importance of having thorough knowledge and a strategic approach when it comes to valve selection.

The triple offset butterfly valve, known for its unique design that offers tight sealing and minimal wear, is increasingly favored in high-pressure applications. Understanding its advantages over traditional valves is essential for engineers and project managers seeking optimal performance. In this article, we will delve into key criteria for selecting the most suitable triple offset butterfly valve, including factors such as pressure ratings, materials, and operational environments, to ensure that your project meets its specific needs with confidence.

Triple offset butterfly valves are engineered for high-performance control in various industrial applications. Their unique design features three offsets that provide a tight seal, making them ideal for handling high-pressure and high-temperature fluids. This valve type is especially suited for applications in the oil and gas, power generation, and water treatment industries, where reliability and efficiency are paramount. By eliminating friction between the seat and disc, triple offset butterfly valves minimize wear and tear, ultimately prolonging service life.

In addition to their robust sealing capability, triple offset butterfly valves are favored for their ease of operation and maintenance. They can be easily automated for remote control, enhancing operational efficiency in complex processes. Furthermore, their lightweight construction allows for easier installation compared to traditional valves, reducing overall project costs. Understanding these applications and operational advantages is crucial for selecting the right valve for your specific project needs, whether you require robust performance or a reliable solution for flow control.

When selecting a triple offset butterfly valve for your project, several key factors must be considered to ensure optimal performance and reliability. First and foremost, evaluate the application's pressure and temperature requirements. Triple offset butterfly valves are designed to handle a wide range of operating conditions, so it is crucial to choose a valve that can withstand the specific demands of your system. Additionally, consider the media being controlled, as different materials and designs can impact compatibility and longevity.

Another vital factor is the size and flow rate of your system. It’s important to ensure that the valve's dimensions align with the pipeline and can accommodate the desired flow without creating unnecessary turbulence or resistance. In many cases, consulting piping charts can provide clarity on the appropriate valve size. Installing a valve that is too small or too large can lead to operational inefficiencies and potential system failures.

Tips: Before making a decision, consult with manufacturers or valve specialists to gain insights into the latest technologies and designs. Also, ensure that you review installation and maintenance requirements, as proper handling can significantly extend the valve's service life. Lastly, consider the warranty and after-sales support offered by suppliers, as these can provide peace of mind for your project’s longevity and performance.

When selecting a triple offset butterfly valve, understanding the materials and construction options available is crucial for ensuring optimal performance and durability for your specific application. The choice of material directly influences the valve's resistance to corrosion, pressure, and temperature variations. Common materials include stainless steel, which offers excellent corrosion resistance and is suitable for a wide range of applications, and carbon steel, ideal for environments where cost considerations are prominent but may require surface treatments for protection. Additionally, specialized alloys can be employed for harsh environments, providing enhanced resistance against aggressive media.

The construction of the valve also plays a significant role in its efficiency and longevity. Triple offset butterfly valves feature a unique design that includes a disc with three offset points; this design minimizes seat wear and provides tight sealing even at higher pressure ratings. Consideration of the valve's sealing materials is vital as well, with options like PTFE, which offers excellent sealing capability and chemical resistance, and other elastomers tailored to specific temperature and pressure conditions. Each option comes with its benefits and limitations, making it essential to assess the operational environment and performance requirements before making a decision. By carefully evaluating the materials and construction options, you can select a valve that not only meets your operational needs but also provides reliability and efficiency.

When selecting a triple offset butterfly valve for your project, understanding sizing and performance requirements is crucial. The valve's sizing must align with the specific application, encompassing factors such as flow rate, pressure, and temperature. Correct sizing ensures that the valve can handle the required flow without excessive pressure drop or risk of cavitation. It is essential to consult flow charts and valve sizing tables to achieve accurate valve dimensions based on the system requirements.

Additionally, performance requirements, such as the valve’s ability to achieve tight shut-off, tightness classifications, and operational lifespan under varying conditions, are vital considerations. Analyzing the pressure and temperature rating in conjunction with the type of media being controlled helps in selecting a valve that can withstand operational stresses. Furthermore, factors like the actuator type and required response time should also be taken into account to optimize performance and reliability. Ensuring that both sizing and performance criteria are met will lead to a successful valve selection tailored for your specific application.

| Valve Size (inches) | Pressure Rating (psi) | Temperature Range (°F) | Body Material | End Connection Type | Applications |

|---|---|---|---|---|---|

| 2 | 150 | -20 to 300 | Carbon Steel | Flange | Water, Oil |

| 4 | 150 | -20 to 300 | Stainless Steel | Flange | Chemical Processing |

| 6 | 300 | -20 to 400 | Ductile Iron | Wafer | HVAC Systems |

| 8 | 150 | -20 to 300 | Aluminum | Lug | Marine Applications |

When selecting a triple offset butterfly valve for your project, it’s crucial to avoid common pitfalls that can lead to inefficiencies and increased costs. One prevalent mistake is overlooking the specifications required by your application. It’s essential to match the valve’s pressure rating, temperature tolerance, and material compatibility with the fluids being controlled. Neglecting these factors can result in premature valve failure or inadequate performance under certain conditions, causing significant operational disruptions.

Another frequent oversight is failing to consider the valve's size and flow requirements. Many projects may underestimate the importance of properly sizing the valve, which can lead to issues such as turbulence, noise, and higher energy consumption. Additionally, it’s important to evaluate the actuator type and control requirements; a mismatch here can complicate installation and compromise the valve's functionality. By paying close attention to these aspects, you can ensure that the butterfly valve you choose will meet the operational needs of your project effectively.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.