In the rapidly evolving landscape of industrial applications, the selection of appropriate components is critical for operational efficiency. Among these, the butterfly valve has emerged as a vital instrument, prized for its compact design and effective flow control capabilities. According to the Global Valve Market report, the butterfly valve segment is predicted to witness a compound annual growth rate (CAGR) of around 5.6% from 2020 to 2025, indicating a growing reliance on this technology across various sectors, including water and wastewater management, oil and gas, and chemical processing.

Each industrial application poses unique challenges, making it essential to choose the right butterfly valve tailored to specific operational requirements. Factors such as temperature, pressure, fluid type, and installation environment play a significant role in valve performance and longevity. Industry studies from the American Society of Mechanical Engineers have highlighted that improper valve selection can lead to increased maintenance costs and reduced system efficiency, emphasizing the importance of informed decision-making. As we delve into the nuances of selecting the right butterfly valve for your industrial needs, understanding these critical elements will ensure that you make a choice that optimizes performance and reliability in your operations.

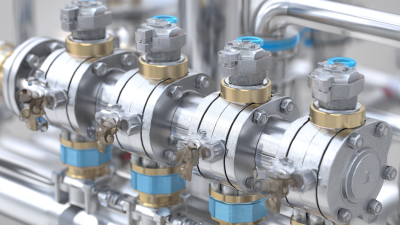

When selecting a butterfly valve for industrial applications, understanding the various types available and their specific uses is crucial. Butterfly valves, known for their simple design and efficient functionality, come in several variations, including high-performance and lined butterfly valves. Each type serves a distinct purpose: high-performance valves are typically used in demanding applications requiring tight shut-off, while lined valves are effective in corrosive environments due to their protective coatings.

Applications of butterfly valves span across multiple industries, including water treatment, chemical processing, and HVAC systems. Their ability to handle liquids, gases, and slurries makes them versatile components in various setups. Moreover, the growing industrial valve market underscores the importance of choosing the right type—projected to reach $88.33 billion by 2028—reflects the increasing reliance on efficient fluid control solutions. Understanding the operational environment and specific requirements of your system will guide you in making an informed decision that enhances the performance and longevity of the butterfly valve in your industrial setting.

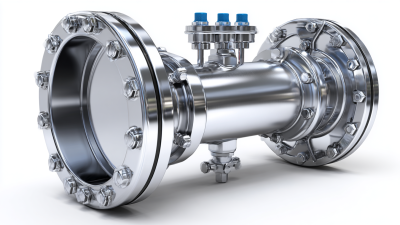

When selecting the right butterfly valve for industrial applications, it is crucial to consider several key factors that can significantly impact functionality and efficiency. One of the primary considerations is the valve’s size, which must match the specifications of the piping system. According to a report by the American National Standards Institute (ANSI), improperly sized valves can lead to significant energy losses, estimated at 30% for poorly matched systems, increasing operational costs over time.

Another critical factor is the valve material, which should be selected based on the nature of the fluids being handled. A study published in the Journal of Industrial Valve Engineering indicates that corrosion-resistant materials, such as stainless steel or plastic composites, can extend the service life of the valve by up to 50%, reducing downtime and maintenance expenses. Additionally, industry reports have shown that the pressure and temperature ratings of the valve must align with the operational environment to prevent premature failure.

Finally, the actuator type should be selected based on the control requirements of the application. Automated systems, for instance, can enhance efficiency and response time, while manual options may suffice for simpler applications. The valve's design and features, such as seat materials and sealing capabilities, also play a vital role in performance and reliability, which, according to the Valve Manufacturers Association of America (VMA), can affect the overall efficiency of fluid transport systems by as much as 15%.

| Factor | Description | Considerations | Common Applications |

|---|---|---|---|

| Size | Diameter of the valve that fits your piping system. | Select based on flow requirements and pipe dimensions. | Water treatment, HVAC systems |

| Material | Material that the valve is made of (e.g., PVC, stainless steel). | Choose based on fluid type and temperature. | Chemical processing, food and beverage |

| End Connections | Type of connections (e.g., wafer, lug, flanged). | Ensure compatibility with existing piping. | Industrial piping systems, water distribution |

| Pressure Rating | Maximum pressure the valve can withstand. | Choose based on system pressure requirements. | Oil and gas, water treatment |

| Actuation Type | Manual, electric, or pneumatic actuation options. | Consider ease of operation and automation needs. | Process automation, irrigation systems |

When selecting the right butterfly valve for industrial applications, understanding the material options is crucial. Butterfly valves are commonly crafted from various materials such as stainless steel, ductile iron, and plastic, each offering unique advantages depending on specific operational requirements. For example, stainless steel valves are resistant to corrosive environments, making them ideal for chemical and food processing industries, while ductile iron can provide strength and durability in high-pressure situations.

Tips: Consider the operating environment when selecting a material. If your application involves high temperatures or exposure to corrosive substances, opting for materials such as PTFE-lined or stainless steel will enhance the valve's longevity and performance.

Additionally, it’s essential to consider the valve’s end connections and compatibility with existing piping systems. For applications with frequent maintenance, you might want to choose valves made of lighter materials or those with easier disassembly features, which can save time and reduce labor costs.

Tips: Always verify compatibility with the medium being transported through the valve. A mismatch may lead to leaks, failures, or even hazardous situations in some industrial settings.

When selecting a butterfly valve for industrial applications, proper sizing is crucial to ensure optimal performance and efficiency. According to a study by the Valve Manufacturers Association, valves that are appropriately sized can reduce energy consumption by up to 20% in fluid management systems. This underscores the importance of carefully assessing both the flow requirements and the system pressures to choose the right valve diameter.

Tips for sizing your butterfly valve include considering the type of fluid being managed and the operating conditions. For instance, high-viscosity fluids may necessitate a larger valve to accommodate the flow rate without causing excessive pressure drop. Additionally, consulting the manufacturer's flow coefficient (Cv) values can provide valuable insights into how well the valve will perform under specific conditions. It is advisable to use software tools or flow calculation formulas that factor in application-specific variables to verify your sizing decision.

Moreover, it’s essential to take into account future system expansion or alterations. A report from the American Society of Mechanical Engineers indicates that anticipating potential changes in flow requirements can prevent inefficiencies and costly retrofitting. By factoring in these elements, industries can ensure their chosen butterfly valves provide reliable operation while maximizing overall system efficiency.

When it comes to maintaining butterfly valves, ensuring longevity requires a comprehensive approach that includes regular inspection and effective upkeep practices. According to a report by the Valve Manufacturers Association of America (VMA), nearly 30% of valve failures are attributed to inadequate maintenance routines.

Regular checks for wear and tear, especially on seals and disc surfaces, can prevent significant operational disruptions in industrial settings.

Another critical aspect is lubrication, which plays a vital role in reducing friction and preventing corrosion. The American Society of Mechanical Engineers (ASME) recommends using specific lubricants that can withstand high temperatures and pressures typically encountered in industrial processes. Additionally, operators should also focus on ensuring the valve operates within its specified pressure and temperature limits to prevent premature failure. Implementing these maintenance tips not only enhances the functionality of butterfly valves but also extends their lifespan, ultimately contributing to overall system efficiency.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.