When selecting the appropriate butterfly valve for any industrial application, understanding the key parameters that influence performance and longevity is crucial. According to a 2022 report by the Valve Manufacturers Association, the global butterfly valve market is projected to grow at a compound annual growth rate (CAGR) of 5.2%, driven by increasing demand in sectors such as oil and gas, water treatment, and power generation. Industry expert John Smith, a senior engineer at Valves International, emphasizes the importance of careful selection, stating, “Choosing the right butterfly valve can significantly enhance system efficiency and reduce maintenance costs over time.”

The right butterfly valve depends on numerous factors, including pressure ratings, temperature ranges, and compatibility with the media being controlled. Different applications necessitate specific design considerations to ensure optimal sealing and flow characteristics. With the rise in automation and smart technologies, the integration of advanced materials and designs in butterfly valve systems is transforming how industries manage fluid control. As industries become more competitive, the right valve selection is no longer just a technical decision but a strategic commitment to operational excellence.

When selecting the right butterfly valve for an application, it is crucial to understand the fundamentals of how these valves operate and where they are best utilized. Butterfly valves are favored for their simple design, which consists of a rotating disc or vane that controls the flow of fluid. They are typically used in applications requiring efficient flow control and quick shut-off capabilities. Understanding materials, sizes, and pressure ratings is vital to ensure the valve can handle specific operational conditions.

In addition to technical specifications, consider the environmental factors that may affect performance. For instance, certain butterfly valves are better suited to handle corrosive substances or extreme temperatures. It's also important to match the valve type to the application's requirements, such as whether the system operates under high pressure or requires a zero-leakage seal. Such considerations are echoed by innovations in related fields, such as the development of container solutions showcased at industry events, emphasizing the relevance of adaptability and efficiency in modern engineering practices.

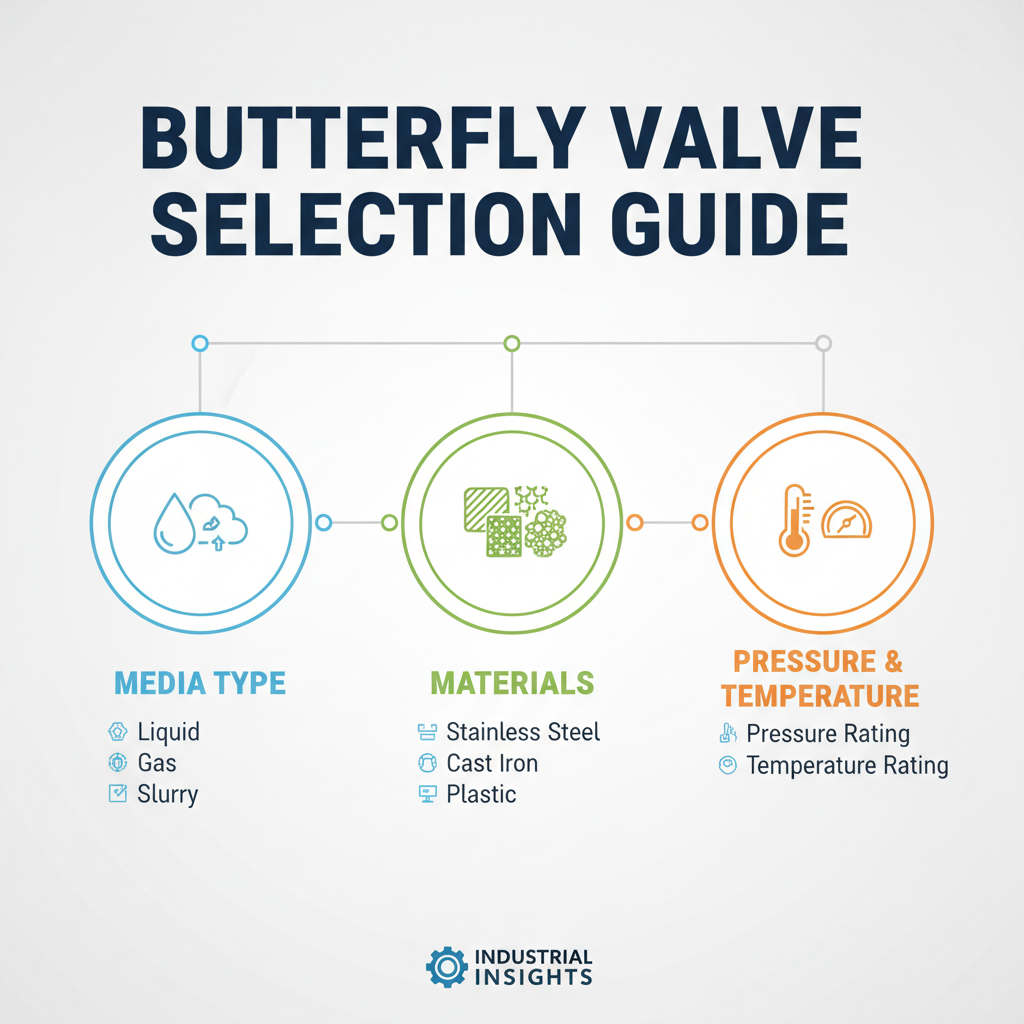

When selecting a butterfly valve for your specific application, several key factors must be considered to ensure optimal performance and reliability. First, understand the type of media that the valve will handle, whether it is a liquid, gas, or slurry. Different materials, such as stainless steel, cast iron, or plastic, are suitable for various media, and choosing the right material is essential to prevent corrosion, wear, and leakage. Additionally, pressure and temperature ratings play a crucial role; you need to ensure the valve can operate effectively under the conditions it will face in your system.

Another important factor is the valve size and mounting style. The valve must fit seamlessly into your system’s layout and accommodate the required flow rates. Consider whether you need a wafer-style or flanged valve, as this will affect the installation process and maintenance accessibility. Furthermore, the desired actuation method—manual, electric, or pneumatic—should align with your operational goals, taking into account ease of use and response time. By thoroughly evaluating these factors, you can select a butterfly valve that meets the demands of your application, ensuring efficiency and longevity in your operations.

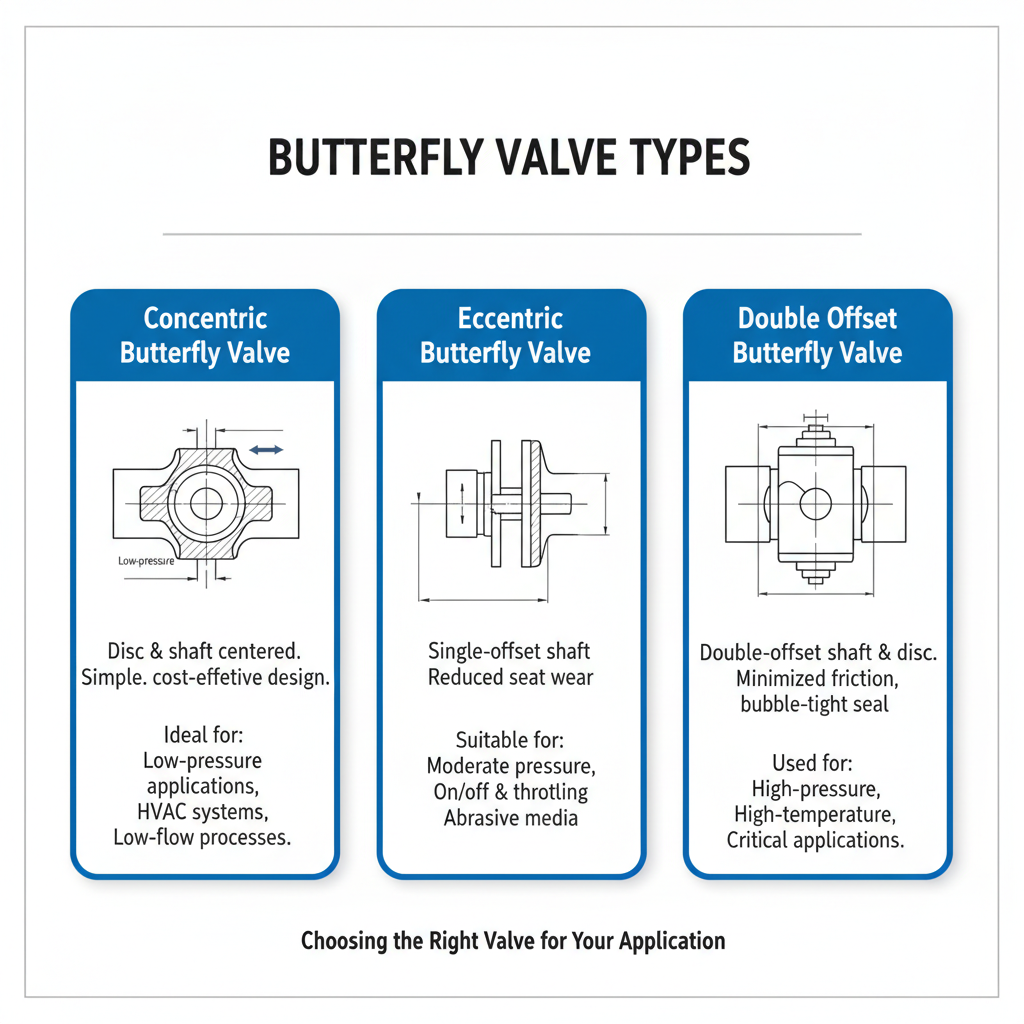

When choosing the right butterfly valve for your application, it's essential to understand the various types available and their specific uses.

Butterfly valves can be classified into three main types: concentric, eccentric, and double offset.

Concentric butterfly valves utilize a simple design where the disc and the shaft are centered on the valve body.

These valves are best suited for low-pressure applications, such as HVAC systems and low-flow processes, due to their straightforward structure and cost-effectiveness.

Eccentric butterfly valves, on the other hand, have an offset disc that allows for a more efficient flow pattern and is designed to minimize turbulence in the pipeline.

This type is ideal for applications with higher pressure requirements, such as in water treatment plants and chemical processing.

Lastly, double offset butterfly valves feature two offsets, providing even greater sealing capabilities and reduced wear, making them suitable for high-temperature and high-pressure applications, including oil and gas industries.

Understanding these distinctions is crucial for selecting the appropriate butterfly valve to ensure optimal performance in your specific application.

When selecting a butterfly valve for specific applications, material selection plays a crucial role, particularly when considering the environmental conditions in which the valve will operate. According to a report from the Valve Manufacturers Association, nearly 40% of valve failures are attributed to material incompatibility with the operational environment. For instance, in corrosive environments, such as chemical processing plants, materials like stainless steel or Hastelloy are often preferred due to their resistance to corrosion and ability to maintain integrity under harsh conditions.

In contrast, for applications involving high temperatures, such as those found in power plants, materials like cast iron or high-temperature alloys are commonly used. The American Society of Mechanical Engineers (ASME) suggests that selecting a material with an appropriate temperature rating can significantly enhance the reliability of the valve, minimizing risks associated with thermal expansion and deformation. In addition, for applications in potable water systems, materials that comply with FDA and NSF standards, such as EPDM or PTFE, are essential to ensure safety and regulatory compliance. Therefore, understanding the specific environmental conditions and regulatory requirements is vital when choosing the right butterfly valve material for optimal performance.

| Environment | Valve Material | Temperature Range (°C) | Pressure Rating (PSI) | Corrosion Resistance |

|---|---|---|---|---|

| Water Treatment | Stainless Steel | -10 to 80 | 150 | Excellent |

| Chemical Processing | PVC | 0 to 60 | 100 | Good |

| Food Processing | Sanitary Stainless Steel | -20 to 90 | 125 | Excellent |

| Oil and Gas | Carbon Steel | -40 to 120 | 300 | Fair |

| HVAC Systems | Aluminum | 5 to 60 | 250 | Good |

When selecting a butterfly valve for your application, avoiding common mistakes can significantly enhance system performance and reliability. One prevalent error is overlooking the velocity of the fluid. According to a report by the Flow Control Magazine, flows exceeding 10 feet per second can lead to noise and erosion, which may compromise valve integrity. It’s essential to align the valve size and type with the anticipated flow characteristics to prevent operational failures.

Another frequent pitfall is neglecting the material compatibility with the fluid being controlled. The Valve Manufacturers Association highlights that using unsuitable materials can result in corrosion and leakages, affecting both safety and efficiency. Always assess the chemical properties of the fluid and choose valves made from materials that can withstand specific conditions, ensuring longevity and reliability.

**Tips:**

1. Perform thorough calculations regarding flow rates and pressure drops to select the correct valve size.

2. Consult with manufacturers about product specifications and material compatibility to avoid costly replacements in the future.

3. Consider the valve's installation environment, as temperature and pressure fluctuations can influence performance.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.