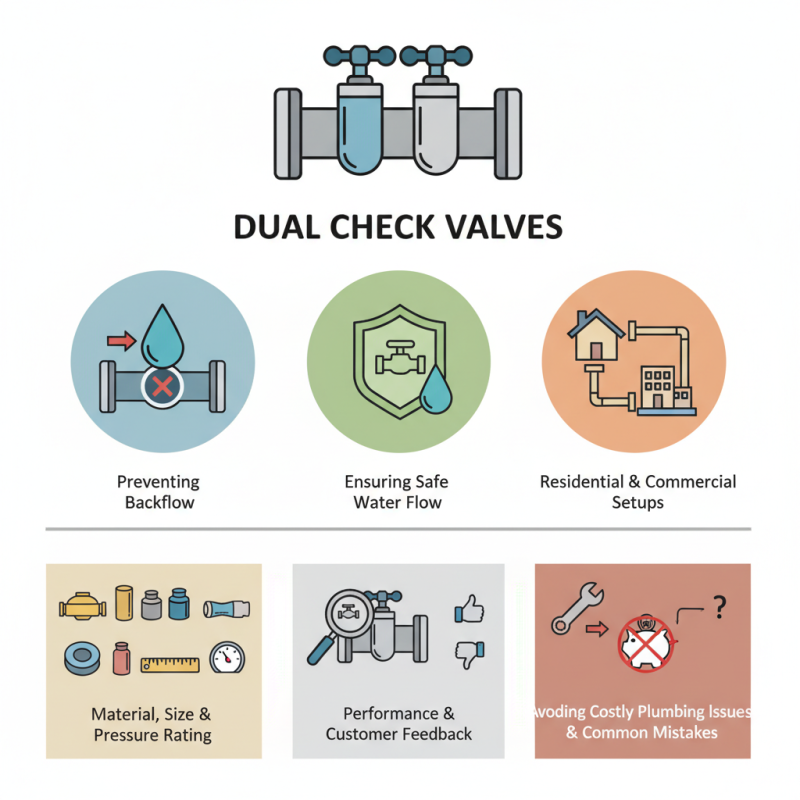

When it comes to plumbing systems, a dual check valve plays a crucial role. It acts as a safeguard, preventing backflow and ensuring safe water flow in residential and commercial setups. Choosing the right dual check valve can be daunting, given the various options available on the market. This buying guide aims to simplify that process, helping you make an informed decision.

Understanding the functionality of a dual check valve is essential. It allows water to flow in one direction while blocking any reverse flow. This mechanism is vital for maintaining water quality. However, not all dual check valves are created equal. Some may leak, while others might not fit your specific needs. Choosing the right one requires careful consideration of factors like material, size, and pressure rating.

In this guide, we will review the best dual check valves available in 2026. This will provide insights based on performance and customer feedback. Identifying the most suitable dual check valve can prevent costly plumbing issues down the road. We will also highlight common mistakes made by buyers. This reflection can help you avoid potential pitfalls while ensuring you choose the best product for your requirements.

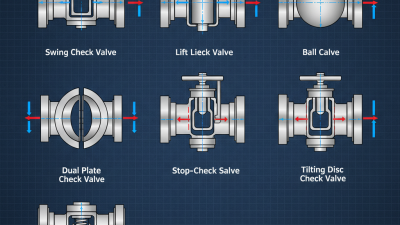

A dual check valve is a mechanical device designed to prevent backflow in plumbing systems. Typically used in water supply lines, it features two check mechanisms that ensure water flows in one direction only. When water attempts to flow backward, the valves close tightly, protecting your system from contamination.

Statistics show that improper backflow can lead to significant health risks, including exposure to harmful bacteria. According to the Water Quality Association, around 70% of waterborne illnesses stem from backflow incidents. This reinforces the importance of having a reliable dual check valve installed in your plumbing systems.

Tips: Regular maintenance of your dual check valve is crucial. Inspect it annually for wear and tear. If it shows signs of leakage, consider replacing it promptly. Additionally, ensure the valve is installed correctly according to plumbing codes. This minimizes the risk of failure.

Many users overlook dual check valve placement. Installing it too close to a pressure regulator can lead to pressure issues. Sometimes, even minor adjustments can enhance the valve's performance. Remember, a well-functioning dual check valve is essential for ensuring clean water supply while preventing plumbing disasters.

When selecting a dual check valve, several key features are crucial for making an informed choice. The body material should be durable and resistant to corrosion. Common materials include brass and PVC. Each material has its own pros and cons. For instance, brass offers longevity while PVC is lighter and often cheaper. It's important to weigh these details carefully.

Another consideration is the valve size. Ensure the valve fits your piping system. Check the specifications before purchasing. A mismatch could lead to leaks or system failures. Additionally, pay attention to the flow rate. A higher flow rate may seem better, but it might not suit your needs. Always evaluate performance requirements.

Lastly, consider the ease of installation. Some models come with detailed manuals and installation kits. Others may lack clarity, which can lead to mistakes. Research reviews to find user experiences about installation ease. This can save you time and potential headaches down the line. Remember, a reliable dual check valve is one that fits well and performs consistently.

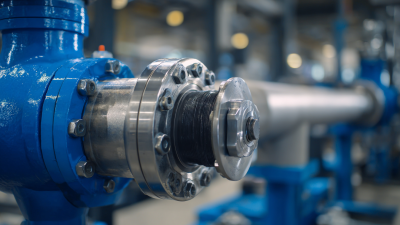

When exploring the top brands and models of dual check valves in 2026, it's essential to understand their distinct features. Many models are designed for specific applications, each with unique advantages. For instance, some offer enhanced durability, while others may focus on compact design. Users often find that the choice depends on their specific needs, such as pressure and flow rate.

Installation can be straightforward, but ensuring compatibility is crucial. Some valves may require additional fittings or adapters. This can create challenges, especially if the wrong model is chosen. Many users overlook the importance of matching their existing systems with the right valve type.

Performance testing is another area worth considering. Some models excel under certain conditions but may falter in others. Feedback from users often highlights performance variations that deserve attention. Regular maintenance cannot be disregarded, as it plays a key role in longevity. Small issues can grow quickly if neglected. Balancing quality and cost is crucial, making informed choices essential when selecting a dual check valve.

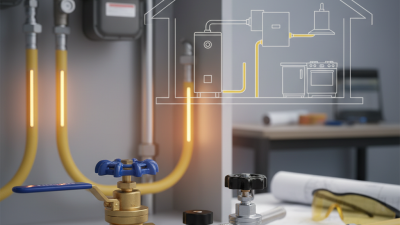

Installing a dual check valve requires careful attention to detail. Begin by selecting an appropriate location for the valve. Ensure it is accessible for maintenance. Ideally, place it close to the source of water. Take time to check for any debris in the pipeline. Sometimes, a simple step like cleaning can make a significant difference.

When connecting the valve, use the right fittings. Don't force components together. Gentle, even pressure helps create a snug fit. It’s essential to align everything properly to prevent leaks. After installation, test the valve for functionality. However, not all installations are perfect. You might notice minor drips or pressure issues. It's worth revisiting the connections. A tight seal often resolves these common problems.

Proper maintenance is crucial for a dual check valve’s longevity. Regularly inspect for signs of wear. Over time, components may degrade. Be proactive in replacing any worn parts. Documenting your maintenance routine is helpful, too. Sometimes, skipping these checks can lead to unexpected issues. Learn from any mistakes; they are part of the process. Keeping a keen eye on your setup can enhance efficiency.

Dual check valves play a crucial role in various plumbing systems. They help prevent backflow, protecting water quality. Proper maintenance ensures they operate efficiently and last longer. Regular checks can prevent costly replacements.

Inspect the valves routinely. Look for signs of wear, such as leaks or corrosion. Clean the valve surfaces to remove debris. Use vinegar or a mild soap solution for cleaning. Avoid harsh chemicals, which can cause damage. Sometimes, you might notice small drips. This is a red flag. Act quickly to avoid bigger problems.

Consider the installation position. Gravity can affect valve performance. Ensure they are installed correctly. Pay attention to the temperature of the fluid. Extreme temperatures can impact the materials. Regular maintenance isn't always done. This oversight can lead to serious issues. Plan periodic inspections to avoid surprises. Your diligence matters.

| Model | Material | Size | Maximum Pressure | Flow Rate | Maintenance Frequency |

|---|---|---|---|---|---|

| Model A | Brass | 1 inch | 150 psi | 20 GPM | Annually |

| Model B | PVC | ¾ inch | 120 psi | 15 GPM | Bi-annually |

| Model C | Stainless Steel | 1.5 inch | 200 psi | 30 GPM | Every 6 months |

| Model D | Copper | 1 inch | 160 psi | 25 GPM | Annually |

| Model E | Plastic | ½ inch | 100 psi | 10 GPM | Every 3 months |

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.