In today's industrial landscape, efficiency and reliability are paramount, driving the need for innovative solutions in fluid control systems. One such solution that has gained considerable traction is the wafer valve. As an essential component in various applications, wafer valves offer unique advantages that cater to the specific demands of modern industries. This article explores the top five benefits of using wafer valves, demonstrating how they can enhance operational performance and contribute to cost-saving measures.

In today's industrial landscape, efficiency and reliability are paramount, driving the need for innovative solutions in fluid control systems. One such solution that has gained considerable traction is the wafer valve. As an essential component in various applications, wafer valves offer unique advantages that cater to the specific demands of modern industries. This article explores the top five benefits of using wafer valves, demonstrating how they can enhance operational performance and contribute to cost-saving measures.

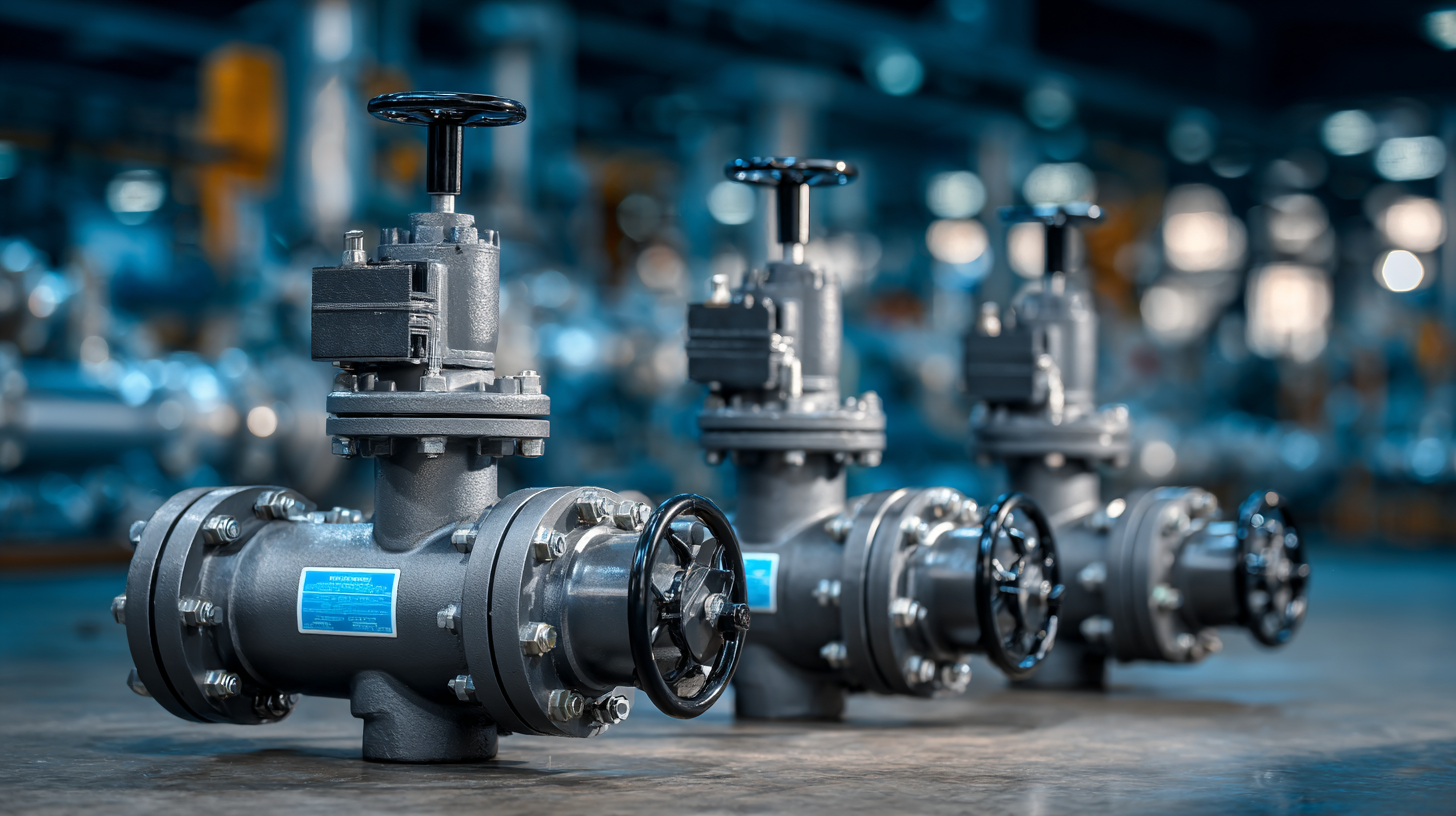

Wafer valves, designed to fit between flanges, provide a compact and lightweight option for fluid management, making them ideal for space-restricted applications. Their ease of installation and maintenance further bolster their appeal to engineers and facility managers alike. With the global shift towards sustainability, wafer valves also play a crucial role in minimizing energy consumption and reducing waste. This discussion aims to highlight the most significant benefits of adopting wafer valves in industrial settings, illustrating why they are considered a forward-thinking choice for 2025 and beyond.

In today's industrial landscape, the need for efficient space utilization is paramount, especially in environments where installation area is limited.

Wafer valves offer significant advantages in tight applications due to their compact design. Unlike traditional flanged valves, wafer valves are lightweight and allow for a reduction in required space between pipe sections. According to a recent report by the International Journal of Engineering Research and Technology, using wafer valves can save up to 30% in installation space, making them ideal for applications in constrained environments, such as chemical processing plants or facilities with limited structural support.

Wafer valves offer significant advantages in tight applications due to their compact design. Unlike traditional flanged valves, wafer valves are lightweight and allow for a reduction in required space between pipe sections. According to a recent report by the International Journal of Engineering Research and Technology, using wafer valves can save up to 30% in installation space, making them ideal for applications in constrained environments, such as chemical processing plants or facilities with limited structural support.

In addition to their space-saving qualities, wafer valves provide exceptional ease of installation and maintenance. Their design allows for a straightforward installation process without the need for heavy equipment, which can lead to time and cost savings during setup. A study by the American Society of Mechanical Engineers (ASME) emphasized that projects using wafer valves often report a decrease in installation time by up to 25%, freeing up resources for other tasks.

Tips for effective implementation of wafer valves in tight spaces include conducting a thorough assessment of the installation area to ensure optimal valve placement and flow direction. Additionally, always consider the valve's pressure ratings and compatibility with the intended medium to avoid unforeseen complications. Proper planning can maximize the benefits of wafer valves, leading to enhanced operational efficiency.

Wafer valves have become increasingly popular in industrial applications due to their compact design and superior performance in flow control. These valves are engineered for efficient operation, ensuring that fluids and gases move seamlessly through pipelines. One of the primary advantages of wafer valves is their ability to provide enhanced flow control efficiency. This is crucial in various industrial processes where precise management of fluids can affect overall productivity and safety.

The unique design of wafer valves allows them to be installed between flanges without the need for additional supports, reducing the potential for leaks and minimizing installation time. Their lightweight construction and low profile enable better maneuverability, making them ideal for spaces where traditional valves may not fit. Moreover, by minimizing turbulence within the flow path, wafer valves facilitate smoother operations, leading to improved energy efficiency and reduced wear on equipment.

This optimized performance ultimately translates into cost savings and a lower environmental impact, making wafer valves a preferred choice for industries seeking reliable and efficient flow control solutions.

In industrial applications, wafer valves are increasingly recognized for their ability to significantly reduce maintenance costs. A report from the International Society of Automation notes that maintenance expenses can account for up to 30% of total operational costs in manufacturing settings. By integrating wafer valves, companies can take advantage of their compact design, which minimizes installation space and helps in reducing wear and tear, a crucial factor that leads to lower maintenance frequencies.

Another industry study from the Valves and Actuators Manufacturers Association indicates that wafer valves not only lower maintenance costs but also enhance system reliability, with failure rates decreasing by up to 25% compared to traditional valve systems. Their streamlined design and fewer components translate into less potential for malfunctions, which can disrupt operations and incur additional repairs.

Tips: When considering the transition to wafer valves, ensure that your team is trained on their unique installation and maintenance requirements. Additionally, regularly monitor the performance metrics of these valves to identify any early signs of issues, further minimizing downtime and maintenance costs. Taking these proactive steps can lead to sustained savings and operational efficiency in your industrial processes.

| Benefit | Description | Impact on Maintenance Costs |

|---|---|---|

| Lower Weight | Wafer valves are lighter than traditional valves, making them easier to handle and install. | Reduced transportation and installation costs. |

| Compact Design | Their space-saving design allows for streamlined piping systems. | Lower installation complexity leads to cost savings. |

| Reduced Leak Points | Fewer connections and seals minimize potential leaks. | Less frequent maintenance needed for leak repairs. |

| Ease of Maintenance | Simple design allows for quick and easy access for repairs. | Decreased labor costs due to faster maintenance times. |

| Lower Operation Costs | Efficient valve operation reduces energy consumption. | Long-term savings on utility bills. |

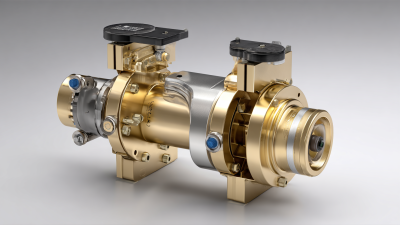

Wafer valves have gained significant traction in industrial applications due to their flexibility and versatility. These compact valves, designed to fit between flanges, offer a lightweight solution that is easy to install and maintain. Their ability to adapt to a variety of piping systems makes them ideal for industries ranging from water treatment to petrochemicals. According to a report by Markets and Markets, the global valve market is projected to reach $88.3 billion by 2024, with wafer valves contributing substantially to this growth through their efficient design and cost-effectiveness.

One of the key advantages of wafer valves is their compatibility with numerous media types and operating conditions. They can handle various temperatures, pressures, and corrosive materials, which is critical in industrial environments where operational flexibility is paramount. A study from Grand View Research highlights that the rising demand for energy-efficient systems and the increasing usage of wafer valves in critical applications, such as HVAC systems, will propel their adoption in the coming years. As industries continue to evolve, wafer valves stand out as a robust solution capable of meeting diverse operational requirements while ensuring reliable performance.

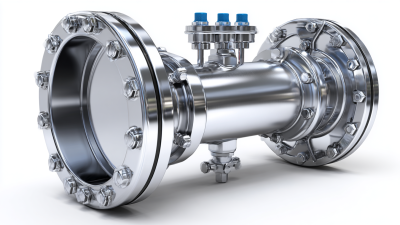

Wafer valves have become increasingly popular in industrial applications due to their lightweight and ease of handling, making them an ideal choice for environments where space and efficiency are critical. Unlike traditional valve designs, wafer valves are compact and require less support, which not only saves on materials but also simplifies installation. This reduction in weight allows for easier manipulation during setup and maintenance, significantly streamlining operational processes.

When considering wafer valves for your industrial needs, it’s essential to prioritize a proper fit within your existing systems. Ensure that the valve size and connection design align correctly with your piping to prevent leaks and operational inefficiencies. Additionally, incorporating handling aids such as slings or trolleys can facilitate the placement and removal of these valves, further enhancing productivity in the workplace.

Another tip is to regularly inspect the wafer valves for wear and tear, even with their lightweight design. Implementing a routine maintenance schedule can prevent unexpected downtimes and prolong the life of the valves, ensuring that they continue to operate efficiently in various industrial applications. With the right approach, wafer valves can significantly enhance both performance and convenience in your operations.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.