The floating valve industry is undergoing significant transformations in 2026. Innovations in materials and designs are making floating valves more efficient and durable. Dr. Emily Hayes, a leading expert in fluid control technologies, once remarked, "The future of floating valves lies in their ability to adapt to new industrial challenges."

Recent trends suggest a greater focus on automation and smart technology. Many manufacturers are integrating sensors that provide real-time data. This adaptability not only enhances performance but also offers cost savings in the long run. However, the path forward is not without concerns. Some innovations may lead to complexities in maintenance and operation.

As industries increasingly depend on floating valves, understanding their advancements becomes crucial. While these changes promise benefits, we must remain aware of their potential pitfalls. It's essential to evaluate both the advantages and the challenges presented by new technologies. Balancing innovation with practical application will define the future of floating valves.

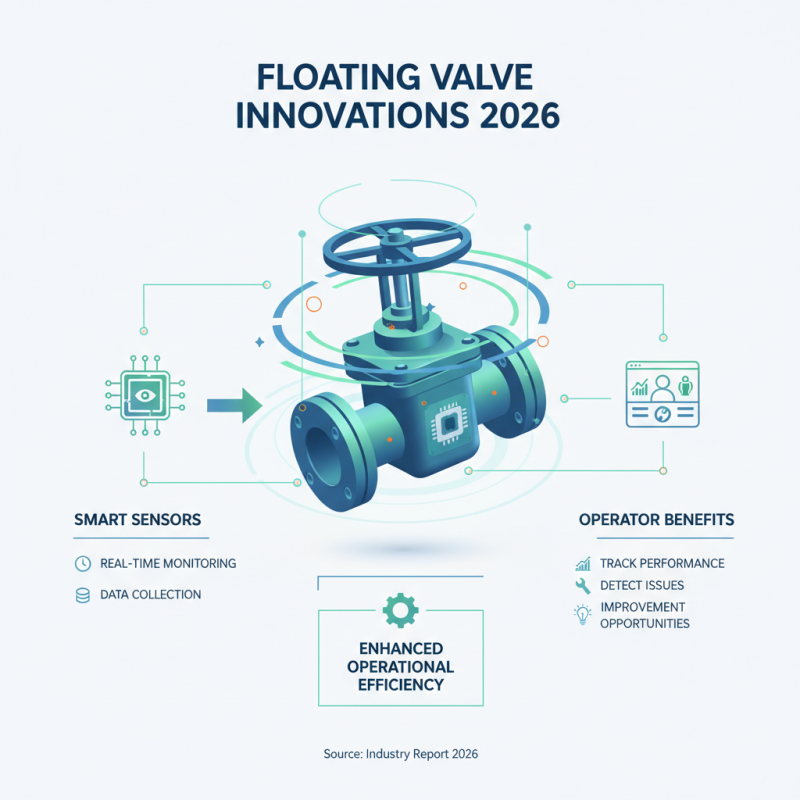

The floating valve industry is witnessing significant innovations, particularly with emerging technologies in 2026. One notable trend is the use of smart sensors integrated into valves. These sensors offer real-time monitoring and data collection, enhancing operational efficiency. Operators can easily track valve performance and detect potential issues and opportunities for improvement.

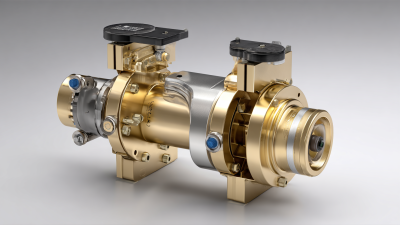

Another technology gaining traction is advanced materials. Traditional materials may not withstand extreme environments. New composites are being engineered for better durability and resistance to corrosion. This shift can lead to increased lifespans for valves and reduced maintenance costs over time. However, using these materials requires careful consideration of the application environment.

There’s also a growing emphasis on sustainability. Industries are pushing for solutions that reduce waste and energy consumption. Floating valves designed with eco-friendly features are becoming more common. Yet, transitioning to these technologies may present challenges. Companies need to weigh up-front costs against long-term benefits. This reflection can be uncomfortable but necessary for growth.

The floating valve market is witnessing exciting developments in 2026. Innovations are heavily driven by the need for greater efficiency and sustainability. Many industrial applications demand valves that not only perform optimally but also conserve resources. This shift is noticeable across various sectors, including water management and oil refining.

Automation is a key trend. More floating valves are now designed with smart technology. Sensors and IoT capabilities enhance monitoring and control. However, some manufacturers struggle to integrate these technologies smoothly. Reliability remains a concern for many operators. They need assurance that these advanced valves can withstand harsh environments.

Another important trend is the emphasis on materials and design. Lightweight materials are gaining popularity. They reduce energy consumption during operations. But, not all designs manage to balance durability and weight effectively. Some floating valves face premature wear, leading to efficiency losses. Continuous improvements in these areas are crucial for future advancements.

The evolution of floating valves is driven by advancements in materials and design, essential for various industrial applications. Recent market reports indicate that the global floating valve market will reach $1.5 billion by 2026, signifying a robust growth predicted by a CAGR of 7.2%. This demand is fueled by industries like oil and gas, where durability and reliability are non-negotiable.

Innovative materials such as advanced composites and high-performance alloys are transforming floating valve design. These materials offer enhanced resistance to corrosive environments, extending the lifespan of valves. For instance, studies show that valves made from composite materials can last up to 50% longer than traditional metal valves. These advancements are crucial for sectors that face harsh conditions regularly.

Yet, challenges remain. Some new materials may not perform as expected under fluctuating temperatures or pressures. There's an ongoing debate about balancing cost and performance with these new designs. Industries must navigate these variables to ensure optimal functionality. Collectively, this pursuit of innovation highlights the need for continuous improvement and adaptation in floating valve technology.

Regulatory demands are shaping the future of floating valves in industrial applications. The market for these valves is expected to grow significantly, projected at a 7.2% CAGR by 2026. Industries must adapt to stricter standards. Compliance with environmental regulations is a key driver. Companies often face challenges in aligning with these standards while innovating.

Safety and efficiency are critical factors. Regulations influence materials used in valve production. For example, the need for corrosion-resistant materials is on the rise. Industry reports indicate that nearly 40% of manufacturers have shifted to more sustainable practices. This change is not just beneficial; it is becoming mandatory.

Innovations in valve technology often lag behind regulatory requirements. Many companies need to invest more in R&D to create compliant solutions. A significant gap exists between current product offerings and regulatory expectations. This inconsistency can lead to increased operational risks and costs. Manufacturers must continuously evaluate their practices to meet evolving regulations while ensuring product effectiveness. The pressure to comply is immense, yet the path towards innovation is fraught with complexities.

The future of smart floating valves in industrial applications is promising and innovative. As industries strive for efficiency, these valves will play a critical role. They can collect real-time data on flow and pressure, aiding decision-making. The integration of IoT technology will enhance their capabilities further. Smart valves will not only automate processes but also monitor their own condition. This self-diagnosis feature reduces maintenance costs and downtime.

Tips: When selecting smart floating valves, consider their adaptability. Compatibility with existing systems is crucial.

Also, think about the types of sensors required for your application.

In terms of installation, proper alignment is key. Misalignment can lead to inefficiencies. Regular feedback from field data will help refine processes. However, not all solutions fit every scenario. Customization might be necessary. Industry-specific challenges must be understood for optimal outcomes.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.